10 Amazing Facts About Air Valves You Didn't Know!

Air valves play a crucial role in various industrial and mechanical applications, yet they often remain underappreciated. These unassuming devices are essential for controlling the flow of air and maintaining system efficiency. In this exploration of "10 Amazing Facts About Air Valves You Didn't Know!", we will delve into the intricacies of air valves, revealing their remarkable features and the innovative technologies behind them. From their unique designs that enhance performance to their significant impact on energy conservation, air valves are more than just functional components; they are pivotal to optimizing systems across multiple industries. Prepare to uncover surprising insights that highlight the sophistication and importance of air valves, ensuring you never look at these devices the same way again!

The Functionality of Air Valves in Modern Engineering

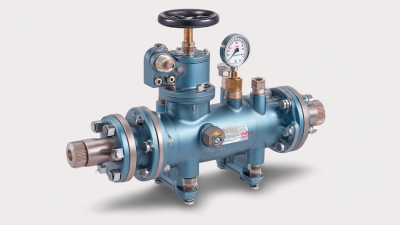

Air valves play a critical role in modern engineering, serving as essential components in various systems, including HVAC, pneumatic machinery, and automotive applications. These devices are designed to regulate airflow, ensuring optimal performance and efficiency. The primary function of air valves is to control the release and entry of air in a system, helping to maintain necessary pressure levels. This functionality prevents backflow and pressure fluctuations that could lead to system inefficiencies or even failures.

In addition to their basic operational role, air valves are engineered to enhance energy efficiency by minimizing leakage and optimizing airflow dynamics. Advanced designs utilize smart technology, allowing for real-time monitoring and control of air flow rates. This integration of innovative mechanisms not only improves overall system reliability but also contributes to sustainability efforts by reducing energy consumption. Ultimately, the functionality of air valves is integral to achieving engineering excellence in both industrial and residential applications, highlighting their importance in modern technological advancements.

Different Types of Air Valves and Their Unique Applications

Air valves are crucial components in various industrial applications, serving to regulate the flow of air and maintain optimal system performance. Among the different types of air valves, the most common include pressure relief valves, vacuum valves, and pneumatic control valves. Pressure relief valves are designed to prevent over-pressurization in systems, ensuring safety and longevity; according to a recent report by the American Society of Mechanical Engineers, improper pressure management contributes to over 20% of mechanical failures in industrial setups.

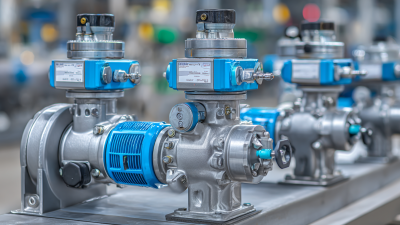

Vacuum valves, on the other hand, play a vital role in systems requiring suction and can be found in industries ranging from food processing to pharmaceuticals. Their efficiency can significantly enhance operational productivity, as highlighted in a study by the International Journal of Mechanical Engineering, which noted that optimized vacuum systems can improve output by up to 30%. Pneumatic control valves, essential for automation, facilitate precise control in various applications, such as in robotics and manufacturing. As automation continues to grow, the global pneumatic valve market is projected to reach approximately $10 billion by 2026, emphasizing the importance of selecting the right type of air valve for specific applications.

10 Amazing Facts About Air Valves You Didn't Know!

| Fact | Type of Air Valve | Unique Application |

|---|---|---|

| Air valves are designed to control the pressure and flow of air in various systems. | Pressure Relief Valves | Used in HVAC systems to release excess pressure and prevent damage. |

| Certain air valves are equipped with sensors for monitoring air quality. | Smart Air Valves | Ideal for modern smart building environmental control. |

| Some air valves can operate both automatically and manually. | Manual/Automatic Air Valves | Used in industrial applications where flexibility is essential. |

| Air valves can help reduce energy costs in heating and cooling systems. | Energy-Efficient Air Valves | Implemented in green buildings to enhance energy saving. |

| Some valves provide a function of air filtration along with airflow control. | Filtration Air Valves | Used in hospital environments to ensure clean air circulation. |

| Air valves have been adapted for use in renewable energy applications. | Wind Turbine Air Valves | Essential for controlling airflow in wind energy systems. |

| They prevent back pressure which can lead to inefficiencies. | Back Pressure Air Valves | Commonly found in exhaust systems to maintain efficiency. |

| Different materials are used in air valve construction for various environments. | Corrosion-Resistant Air Valves | Application in marine or chemical processing environments. |

| Air valves are crucial for vehicle systems as well. | Automotive Air Valves | Manage air intake for optimized engine performance. |

| Innovative designs are leading to smaller and more efficient valves. | Compact Air Valves | Perfect for space-constrained applications like drones. |

How Air Valves Contribute to Energy Efficiency

Air valves play a crucial role in enhancing energy efficiency in various systems. By allowing controlled airflow, these valves ensure optimal performance in heating, ventilation, and air conditioning (HVAC) systems. They prevent the loss of conditioned air, which can lead to wasted energy and increased costs. The strategic placement of air valves can significantly reduce the workload on HVAC units, leading to lower energy consumption and extended equipment lifespan.

Tip: Regularly inspect and maintain air valves to ensure they function properly. Dust and debris can accumulate and hinder their operation, leading to inefficiencies.

Another fascinating aspect of air valves is their ability to improve indoor air quality. By managing airflow and maintaining balanced pressure within ducts, these valves prevent the buildup of harmful pollutants. This controlled environment not only supports energy efficiency but also promotes healthier living spaces.

Tip: Consider investing in automatic air valves with sensors that adjust settings in real-time, responding to changes in occupancy and activity levels to optimize energy use continually.

The Technology Behind Advanced Air Valve Designs

Air valves play a crucial role in various applications, from HVAC systems to industrial processes, and their advanced designs are rooted in cutting-edge technology. The core function of an air valve is to control airflow, ensuring that systems operate efficiently. Technologies such as variable geometry, electronically controlled actuators, and advanced sensor integration have significantly improved the performance of these valves. These innovations allow for more responsive and precise control of airflow, leading to energy savings and enhanced system reliability.

Moreover, the materials used in advanced air valve designs contribute to their effectiveness. Lightweight and durable composites, along with advanced sealing technologies, enhance the longevity and reliability of air valves, reducing maintenance needs and costs. Additionally, the incorporation of smart technology allows for real-time monitoring and diagnostics, providing operators with valuable data to optimize system performance. As air valve technology continues to evolve, it is poised to play an even more integral role in creating sustainable and efficient systems across various industries.

10 Amazing Facts About Air Valves

This bar chart displays average specifications of air valves, highlighting their durability, operational efficiency, pressure rating, weight, and cost. These factors illustrate the advanced technology behind modern air valve designs.

Common Misconceptions About Air Valves Explained

When discussing air valves, it's crucial to address common misconceptions that often lead to improper installation and usage. One prevalent myth is that all air valves function the same way; however, different air valves serve distinct purposes, such as preventing air from entering systems or facilitating air release during operation. This misunderstanding can result in inefficient system performance and potential damage if the wrong type of valve is used in specific applications.

Another widespread misconception revolves around the maintenance of air valves. Some believe that once installed, air valves require little to no attention. In reality, regular checks are necessary to ensure they are functioning correctly and not clogged with debris. Neglecting maintenance can lead to air blockage, which impacts system efficiency and longevity. Understanding these misconceptions is essential for anyone working with hydronic systems, as accurate knowledge leads to better performance and reliability in HVAC setups.

Related Posts

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

How to Choose the Best Solenoid Valves for Your Industrial Applications

-

7 Essential Features of Small Pneumatic Valves You Should Know About

-

Mastering Pneumatic Flow Control Valves A Comprehensive Guide for Global Buyers