How to Choose the Right Diaphragm Valve for Your Industrial Applications

In the rapidly evolving industrial landscape, the selection of the appropriate diaphragm valves is critical for optimizing processes and ensuring operational efficiency. According to a recent report by Research and Markets, the global diaphragm valves market is projected to reach USD 4.2 billion by 2025, driven by increasing demand across various sectors, including water treatment, pharmaceuticals, and food processing. Diaphragm valves are revered for their ability to provide tight sealing, excellent flow control, and minimal leakage, making them indispensable in applications where contamination must be avoided. However, with diverse types and specifications available, choosing the right diaphragm valve becomes a significant challenge for engineers and procurement specialists. Understanding the unique requirements of your application—ranging from fluid characteristics to pressure and temperature constraints—will guide you in making an informed decision that enhances both reliability and efficiency in your industrial operations.

Understanding the Basics of Diaphragm Valves in Industrial Settings

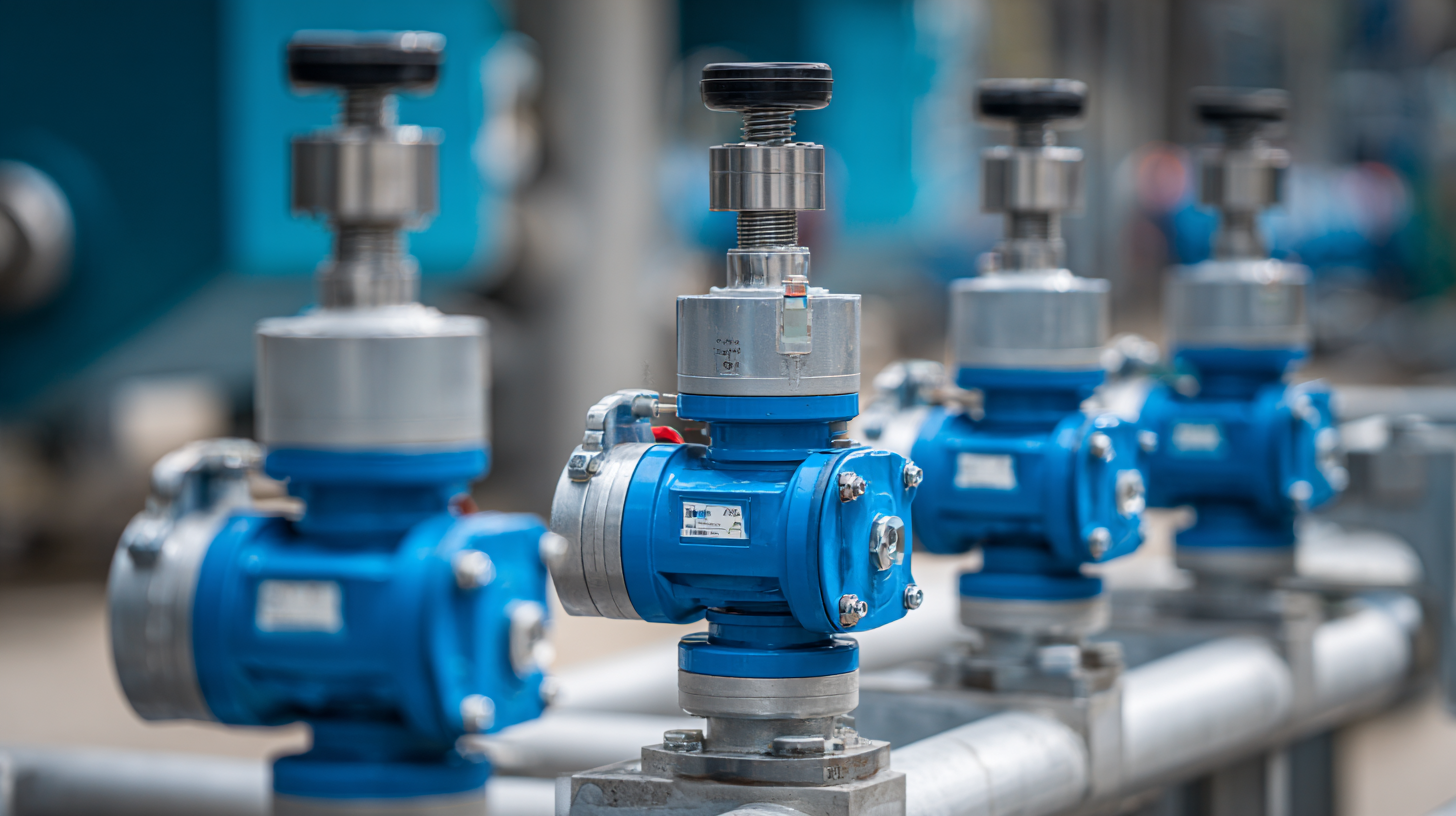

Diaphragm valves are essential components in various industrial applications, primarily designed to control fluid flow while preventing contamination. Their unique design, featuring a flexible diaphragm that seals against a valve seat, allows for precise flow regulation and isolation of sensitive fluids. Understanding the basics of diaphragm valves is crucial for selecting the right valve for your specific needs.

When choosing diaphragm valves, consider factors such as the fluid's temperature, pressure, and chemical compatibility. The material of the diaphragm and the valve body are critical in ensuring longevity and reliable performance. Additionally, the valve's size and connection type must align with the existing piping system.

Tips: Always consult the manufacturer’s specifications and performance charts to ensure compatibility. It’s also beneficial to conduct regular maintenance checks on diaphragm valves to prevent leaks and ensure optimal operation. Finally, consider integrating automation systems that can enhance the efficiency and precision of diaphragm valve operations in your facility.

Key Factors to Consider When Selecting Diaphragm Valves

When selecting diaphragm valves for industrial applications, several key factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the material compatibility of the valve with the media it will control. According to a report by Research and Markets, the rising demand for diaphragm valves in pharmaceuticals and food processing industries has propelled the adoption of materials like PTFE and EPDM, which provide excellent chemical resistance. Ensuring that the diaphragm material is compatible with the fluid's temperature and pH levels can significantly enhance the valve's lifespan and efficiency.

Another crucial factor is the valve's pressure rating. The global diaphragm valve market is projected to reach $2.9 billion by 2027, underscoring the importance of selecting valves that can withstand the operational pressures specific to your industry. For instance, in high-pressure applications, choosing valves with a robust design and the appropriate actuator type can prevent failures and leaks. Additionally, the size and flow rate capabilities of the diaphragm valve must align with the system requirements—larger valves accommodate higher flow rates, while smaller valves are better suited for precision control in low-flow situations. Taking these factors into account will ensure that your diaphragm valve selection meets the demands of your specific industrial application effectively.

How to Choose the Right Diaphragm Valve for Your Industrial Applications

| Key Factor | Description | Considerations |

|---|---|---|

| Material Compatibility | Ensure the valve material is suitable for the media being handled. | Check for abrasion, corrosion, and chemical resistance. |

| Pressure Rating | The valve should be able to withstand the maximum pressure of the application. | Review pressure requirements specific to your process. |

| Temperature Range | Select a valve that operates effectively within your temperature requirements. | Consider both operating and ambient temperatures. |

| Flow Requirements | Determine the desired flow rate needed for your application. | Use appropriate sizing calculations for optimal performance. |

| Actuation Method | Choose between manual, pneumatic, or electric actuation based on application needs. | Assess ease of operation and control requirements. |

Material Compatibility: Choosing the Right Diaphragm for Your Needs

When selecting the right diaphragm valve for your industrial applications, material compatibility is a critical factor that should not be overlooked. Diaphragms are available in various materials, each suited to different types of fluids and environmental conditions. Understanding the chemical properties of the fluids being handled is essential in order to choose a diaphragm that can withstand aggressive substances without breaking down or corroding. For instance, elastomers like EPDM and FKM are commonly used for their resilience against a wide range of chemicals, while thermoplastics can be more suited for less aggressive environments.

Another important consideration is temperature and pressure conditions. High temperatures and pressures may require specialized materials that can maintain their integrity under stress. Selecting a diaphragm made from materials like PTFE can provide excellent thermal stability and chemical resistance, making it ideal for many demanding applications. Additionally, industry standards and certifications should be taken into account to ensure that the chosen diaphragm meets the necessary safety and performance requirements for your specific industrial setting.

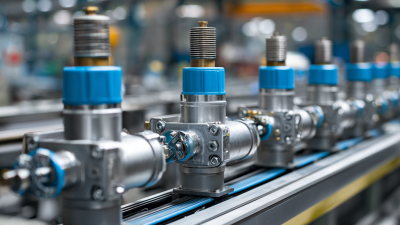

Evaluating Flow Conditions and Pressure Requirements for Diaphragm Valves

When selecting a diaphragm valve for industrial applications, understanding the flow conditions and pressure requirements is paramount. According to a report by the International Journal of Engineering Research, diaphragm valves are particularly suitable for controlling fluid flow in systems with varying pressure conditions, often tolerating pressure ranges from vacuum to 150 psi. In high-pressure scenarios, materials such as PTFE and elastomers can maintain integrity, reducing the risk of material failure under stress.

Moreover, flow conditions play a critical role in diaphragm valve selection. A study published in the Journal of Fluid Mechanics highlights that the valve's design can impact flow rates significantly, with certain configurations enhancing efficiency in turbulent flow environments. Industries such as chemical processing and wastewater management rely on precise control of both flow rates and pressure to maintain safety and productivity, emphasizing the necessity of thorough evaluation in the selection process. By considering specific flow characteristics and pressure ratings outlined in these industry reports, engineers can ensure optimal performance and longevity of diaphragm valves in their applications.

Maintenance and Durability Considerations for Long-Term Performance

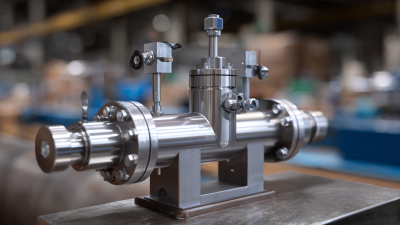

When selecting a diaphragm valve for industrial applications, maintenance and durability are critical factors that influence long-term performance. According to a report by the American Association of Mechanical Engineers (AAME), improper maintenance can reduce valve lifespan by up to 30%. Regular inspection and servicing are essential to identify issues such as membrane wear, which typically occurs in high-stress environments, leading to leaks and reduced efficiency. Implementing a proactive maintenance schedule can help mitigate these risks, ensuring the valve remains operational and reliable over time.

Durability is also influenced by the material selection of the diaphragm valve. A study published in the Journal of Industrial Equipment and Applications reveals that valves made from high-grade elastomers and thermoplastics can withstand extreme temperatures and corrosive chemicals, extending their usability by an average of 25%. Additionally, valves with external coatings offer enhanced protection against environmental factors, further promoting longevity. By understanding these maintenance and durability considerations, industries can optimize their valve selection process, ultimately improving their operational efficiency and reducing downtime.

Related Posts

-

How to Select the Right Diaphragm Valves for Your Industrial Applications

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

-

Unlocking Precision in Fluid Dynamics with the Best Liquid Flow Control Valve Technical Specifications and Best Practices

-

7 Compelling Reasons to Choose Industrial Control Valves for Your Global Sourcing Needs

-

Mastering Pneumatic Flow Control Valves A Comprehensive Guide for Global Buyers