How to Choose the Right Liquid Flow Control Valve for Your Applications

Choosing the right liquid flow control valve is essential for ensuring optimal performance and efficiency in various applications. These valves play a crucial role in regulating the flow of liquids, which is vital in industries ranging from manufacturing and food processing to pharmaceuticals and water treatment. With a multitude of options available in the market, making the right choice can be overwhelming. It requires a comprehensive understanding of the specific requirements of your application, including flow rates, pressure ranges, and the nature of the liquids being handled.

Moreover, the selection process must consider factors such as valve materials, size, and the control methods available. For instance, different applications might demand precise flow control or the ability to withstand harsh environmental conditions. Understanding these variables is key to identifying the most suitable liquid flow control valve that not only meets the operational demands but also enhances the overall system reliability. By carefully evaluating these factors, you can ensure that your choice contributes to the efficiency and longevity of your operational processes.

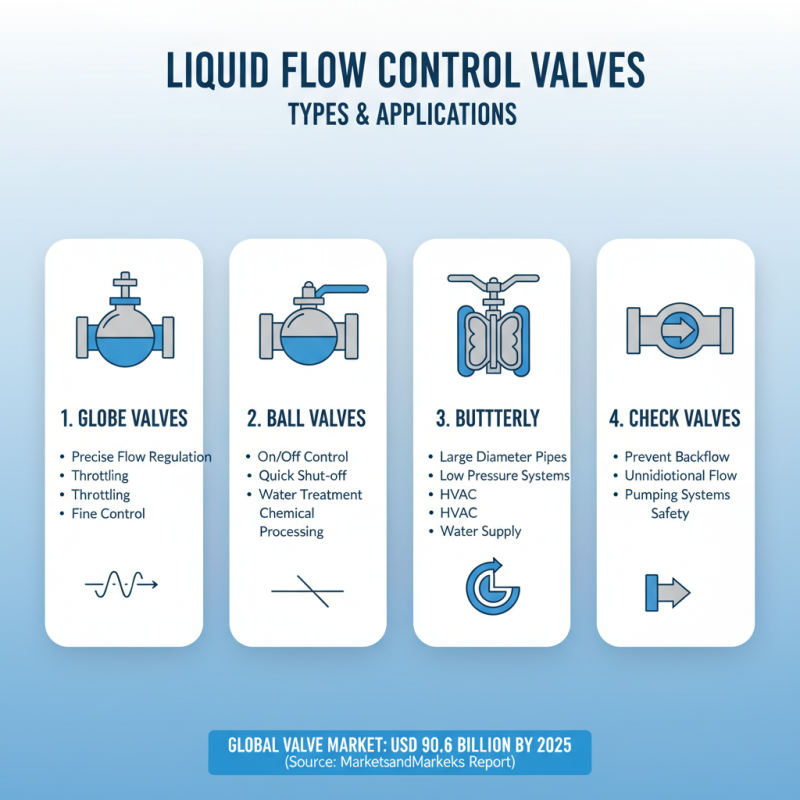

Types of Liquid Flow Control Valves and Their Applications

When selecting the appropriate liquid flow control valve, understanding the types available and their specific applications is crucial. Generally, liquid flow control valves can be categorized into four main types: globe valves, ball valves, butterfly valves, and check valves. Globe valves are often utilized in applications requiring precise flow regulation due to their ability to throttle flow effectively. On the other hand, ball valves are favored for on/off control and are prevalent in industries where quick shut-off is required, such as water treatment and chemical processing. According to a report by MarketsandMarkets, the global valve market is expected to reach USD 90.6 billion by 2025, indicating a steady demand across various sectors.

Butterfly valves are another popular option, particularly in large-scale applications like HVAC systems, thanks to their lightweight design and low-pressure drop. In contrast, check valves play a vital role in preventing backflow in pipelines, which is critical for maintaining system integrity and preventing contamination. A detailed analysis from Research and Markets reveals that the demand for check valves is projected to grow significantly, driven by the rising needs in wastewater management and oil & gas industries.

**Tips:** When selecting a flow control valve, always consider the fluid type, pressure, and temperature of your application to ensure compatibility. Additionally, reviewing manufacturer specifications and industry standards can provide crucial guidance to ensure your choice meets regulatory requirements and operational efficiency.

Key Factors to Consider When Selecting a Flow Control Valve

When selecting a liquid flow control valve, several key factors should be considered to ensure optimal performance for your specific applications. First, understanding the fluid characteristics—such as viscosity, density, and temperature—is crucial. These properties can significantly impact the valve's performance and lifespan. Selecting a valve that can withstand the chemical properties of the fluid is equally important to prevent corrosion or blockage.

Another essential factor is the flow rate requirements. Determine the maximum and minimum flow rates your application demands, as well as the pressure drop across the valve. This information will help you choose a valve size that can regulate flow effectively without causing excessive energy loss.

Tips: To streamline your selection process, it can be beneficial to create a flow chart of your system's requirements, accounting for variables like pressure and temperature. Additionally, consulting with technical experts or utilizing software tools for simulation can provide insights that simplify your choice.

Lastly, consider the type of actuation you prefer—manual, pneumatic, or electric. Each type offers distinct advantages depending on your application’s needs for automation and control precision. Ensure that the valve you choose aligns with operational requirements to enhance system efficiency and reliability.

Understanding Flow Rate, Pressure, and Temperature Requirements

When selecting the right liquid flow control valve for your specific applications, understanding the flow rate requirement is crucial. Flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), directly impacts the efficiency and performance of the system. According to a recent report by the Fluid Control Institute, optimizing flow rates can lead to up to a 25% increase in system efficiency. Ensuring the valve can handle the required flow rate without causing turbulence or pressure loss is essential, as pressure drops of even a few psi can lead to significant inefficiencies.

In addition to flow rate, pressure and temperature requirements significantly influence valve selection. The American Society of Mechanical Engineers (ASME) indicates that operating temperatures can affect the material choices for valves; for example, certain plastics may not withstand high-temperature fluids. It’s essential to choose valves that can operate safely within the specified pressure range, as exceeding this threshold risks valve failure or system leaks. A study from the International Journal of Fluid Mechanics found that selecting appropriate valve types for specific pressure needs could reduce maintenance costs by nearly 30%. Therefore, thoroughly evaluating these parameters—flow rate, pressure, and temperature—ensures not only optimal valve performance but also the longevity of the entire system.

Material Compatibility and Its Importance in Valve Selection

When selecting a liquid flow control valve, material compatibility is a critical factor that cannot be overlooked. The interaction between the valve materials and the fluid being controlled can significantly affect the performance, longevity, and safety of the system. A report from the Fluid Control Association highlights that around 30% of valve failures in industrial applications are attributed to improper material selection, leading to leaks and potential system downtime. This underscores the necessity of choosing materials that can withstand specific chemical properties of the fluids, such as corrosiveness, temperature, and pressure.

For instance, when dealing with corrosive liquids, materials like stainless steel or specialized plastics might be preferred due to their resistance to chemical reactions. The American National Standards Institute (ANSI) suggests that compatibility assessments should take into account factors such as pH levels and temperature ranges. Furthermore, industry data points out that improper material selection can lead to reduced flow efficiency and increased maintenance costs, further emphasizing the importance of thorough analysis before making a decision. Proper material selection not only enhances the reliability and efficiency of fluid control systems but also contributes to a safer operational environment.

How to Choose the Right Liquid Flow Control Valve for Your Applications - Material Compatibility and Its Importance in Valve Selection

| Dimension | Description | Material Compatibility | Ideal Applications |

|---|---|---|---|

| DN15 | 15 mm nominal diameter | Stainless Steel, PTFE | Chemical processing, food and beverage |

| DN25 | 25 mm nominal diameter | Brass, NBR | Water supply, HVAC |

| DN50 | 50 mm nominal diameter | PVC, EPDM | Irrigation, wastewater treatment |

| DN100 | 100 mm nominal diameter | Carbon Steel, Viton | Oil and gas, industrial fluid control |

Maintenance and Longevity Considerations for Flow Control Valves

When it comes to maintaining liquid flow control valves, regular inspection and servicing are paramount to ensure their longevity and reliable performance. Consideration should be given to the operating environment, as factors such as temperature extremes, pressure variations, and exposure to corrosive materials can significantly impact valve integrity. Scheduled maintenance routines that include cleaning, lubrication, and examination of seals and components can help identify potential issues before they result in operational failures.

In addition to routine maintenance, the selection of materials is crucial for extending the lifespan of flow control valves. Choosing the right materials based on the specific application can prevent premature wear and tear. For instance, stainless steel or specialized coatings might be necessary in corrosive environments, while specific elastomers may be ideal for high-temperature applications. Understanding the flow characteristics and fluid properties can also dictate the design and specifications of the valve, ultimately contributing to its longevity and efficiency in managing fluid dynamics. Ensuring that these considerations are part of the initial selection process can reduce long-term costs associated with unscheduled repairs and replacements.

Liquid Flow Control Valve Performance Comparison

This chart compares the performance of different liquid flow control valves in terms of their maximum flow rates and pressure drops. It assists in choosing the right valve for specific applications by highlighting their maintenance and longevity considerations.

Related Posts

-

Exploring Key Specifications for the Best Industrial Control Valves and How to Choose the Right One

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

How to Efficiently Utilize Air Flow Valves for Optimal System Performance

-

7 Essential Features of Small Pneumatic Valves You Should Know About

-

Top 10 Control Valves for Efficient Fluid Management in Industrial Applications

-

7 Compelling Reasons to Choose Industrial Control Valves for Your Global Sourcing Needs