Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

The demand for high-quality air solenoid valves is on the rise, driven by advancements in automation and industrial applications. According to a recent report by MarketsandMarkets, the global solenoid valves market is expected to grow from USD 2.17 billion in 2020 to USD 3.38 billion by 2025, with a significant focus on improving efficiency and reliability in various industries. As businesses seek to enhance operational performance and minimize downtime, selecting the right manufacturer for air solenoid valves becomes crucial. The right manufacturer not only ensures compliance with stringent industry standards but also provides innovative solutions tailored to specific applications. In this blog, we will explore key factors to consider when choosing a manufacturer for high-quality air solenoid valve solutions, helping you make informed decisions that align with your operational goals.

Understanding Industry Standards for Air Solenoid Valve Manufacturing

When selecting a manufacturer for high-quality air solenoid valves, understanding industry standards is crucial. These standards ensure that the valves meet the requisite safety, performance, and reliability criteria. Familiarizing yourself with pertinent certifications, such as ISO 9001 and CE marking, can help gauge the manufacturer's commitment to quality and adherence to international regulations.

**Tip:** Always inquire about the manufacturer's quality control processes. A robust quality management system signifies that the manufacturer prioritizes product excellence and consistency.

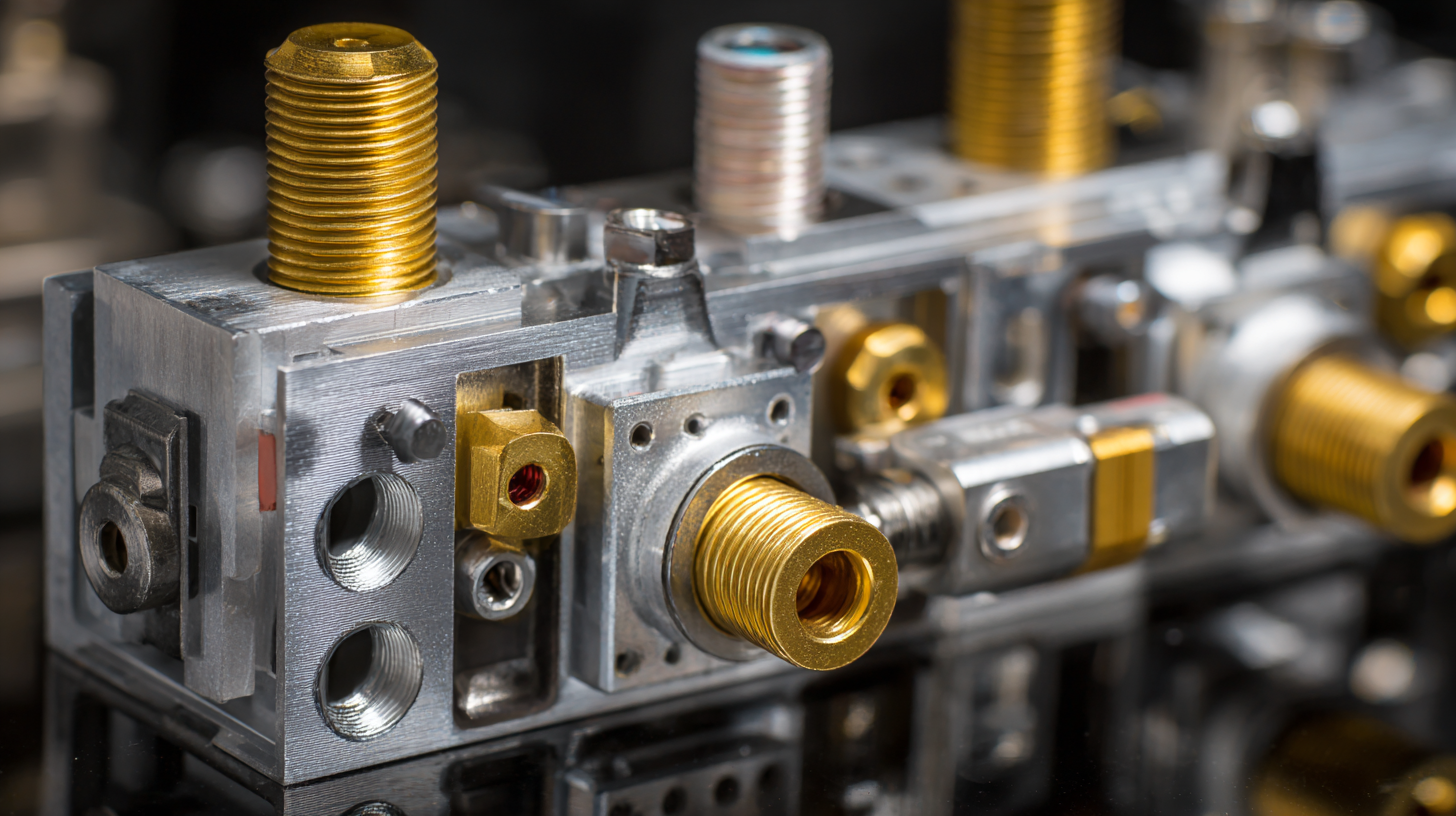

Additionally, it’s essential to evaluate the materials used in the manufacturing process. High-quality raw materials contribute to the durability and longevity of air solenoid valves. Manufacturers should comply with material specifications set by industry standards, which enhances overall product performance in demanding applications.

**Tip:** Request detailed specifications and test results from the manufacturer. Understanding the material grades and testing methods they utilize can provide insight into the valve's projected lifespan and reliability under various operating conditions.

Key Factors Influencing the Quality of Air Solenoid Valves

When selecting a manufacturer for high-quality air solenoid valves, several key factors should be considered to ensure optimal performance and longevity. The design and materials used play a crucial role in determining the valve's reliability. For instance, high-grade materials can significantly resist wear and corrosion, enhancing the valve's lifespan under varying pressures and temperatures. Additionally, precision in engineering is essential; even slight deviations can affect the flow rates and operational efficiency of the valves.

Tips: Always inquire about the manufacturer’s testing processes. A reputable manufacturer should conduct rigorous quality control tests, including pressure testing and thermal cycling, to validate the functionality of their solenoid valves. Additionally, consider the manufacturer’s reputation in the industry. Reviews and case studies can provide insights into their reliability and customer satisfaction.

Another critical aspect is the technological advancements employed by the manufacturer. Companies utilizing modern techniques, such as AI models for predictive maintenance or intelligent monitoring systems, indicate a commitment to innovation and enhanced performance. This can lead to more dependable and efficient operations, which is particularly important in applications requiring precise control, like in automatic transmissions or agricultural machinery.

Tips: Evaluate whether the manufacturer offers customization options that suit your specific application needs, as tailored solutions often yield better performance than standard products.

Essential Certifications for Reliable Solenoid Valve Manufacturers

When selecting a manufacturer for high-quality air solenoid valve solutions, understanding essential certifications is crucial. Manufacturers that have achieved ISO 9001 certification demonstrate their commitment to quality management standards. According to a report by Grand View Research, the global solenoid valve market is projected to reach $7.43 billion by 2025, driven by the increasing demand for automation across various industries. This growth underscores the importance of partnering with certified manufacturers to ensure product reliability and performance.

Additionally, certifications such as CE and UL mark a manufacturer's adherence to safety and environmental standards. Solenoid valves are often employed in critical applications ranging from automotive systems to industrial automation; therefore, compliance with these standards is vital. A study from the MarketsandMarkets report highlights that the industrial automation sector is expected to grow at a CAGR of 9.4%, further emphasizing the need for certified components. Choosing a manufacturer with the right certifications not only ensures the quality of the valves but also their compliance with industry regulations, ultimately leading to operational efficiency and safety.

The Role of Advanced Technology in Enhancing Valve Performance

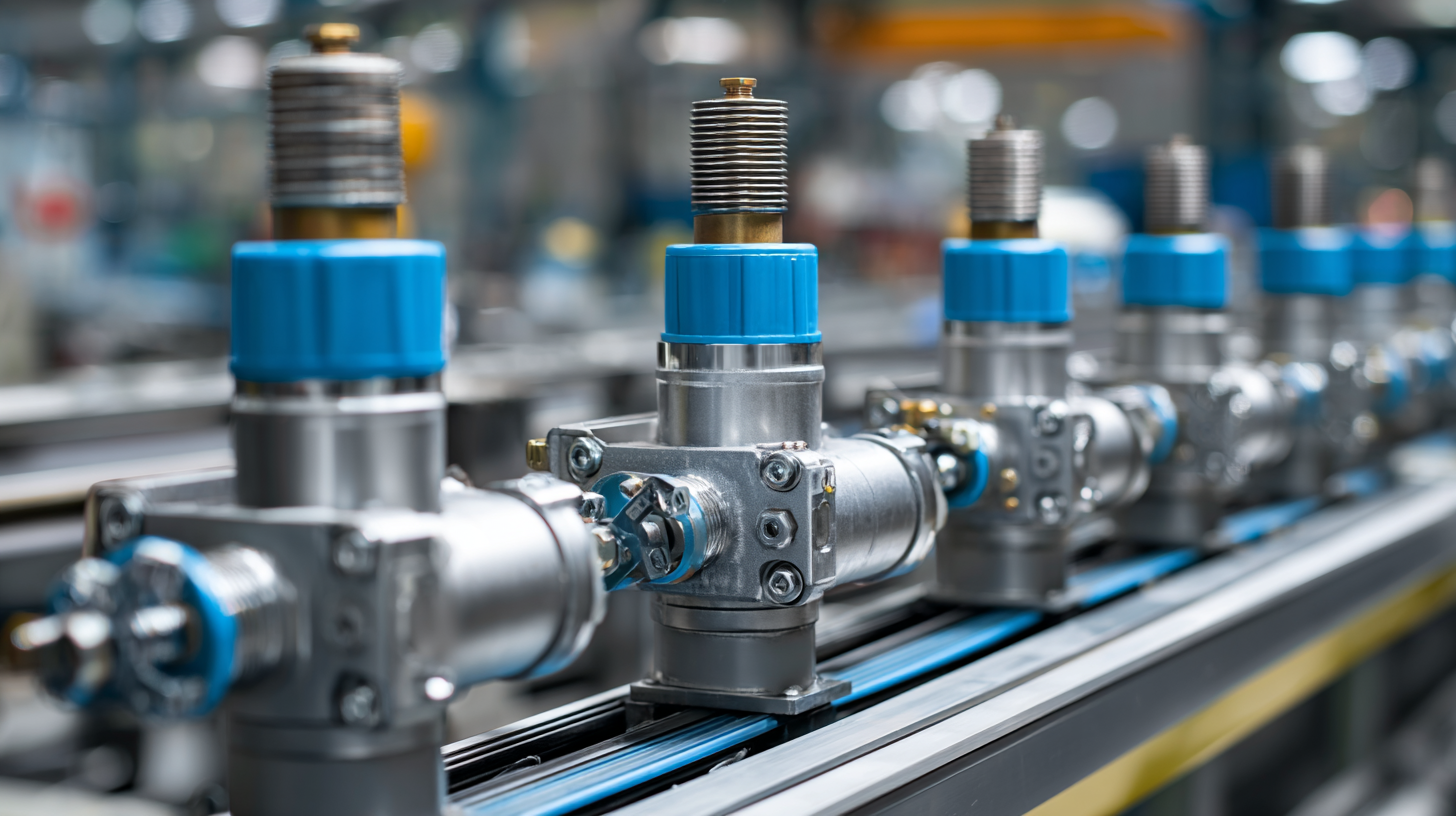

The evolution of air solenoid valves has been significantly driven by advanced technology, which plays a pivotal role in enhancing their performance and reliability. With the integration of smart sensors and automation systems, modern solenoid valves are now capable of providing real-time feedback and diagnostics. This capability allows manufacturers to ensure optimal operation and immediate response to any anomalies, ultimately boosting efficiency and reducing downtime in various applications.

Moreover, the use of advanced materials and precision engineering techniques has resulted in valves that not only perform better but also exhibit increased durability and resistance to wear and tear. These innovations enable solenoid valves to operate effectively in demanding environments, making them suitable for sectors like manufacturing, automotive, and aerospace. As technology continues to advance, the potential for improved energy efficiency and streamlined designs becomes a key factor for businesses seeking high-quality solenoid valve solutions, ensuring they remain competitive in a rapidly evolving market.

High Quality Air Solenoid Valve Solutions: Performance Metrics

Evaluating Manufacturer Reputation through Customer Feedback and Case Studies

Choosing the right manufacturer for high-quality air solenoid valve solutions is essential for businesses aiming to optimize their operations. One of the most effective ways to evaluate potential manufacturers is through customer feedback and case studies. According to a recent report, 79% of consumers trust online reviews as much as personal recommendations, highlighting the significance of real customer experiences in the decision-making process. By analyzing feedback from various customers, companies can discern the reliability and performance of different manufacturers in the competitive solenoid valve market.

In addition, case studies serve as powerful tools to assess a manufacturer's capability to deliver on expectations. For instance, successful collaborations between manufacturers and businesses can provide insights into product quality, design flexibility, and after-sales support. A survey indicated that 86% of buyers are willing to pay more for a better customer experience, reinforcing the notion that operational success often hinges on the manufacturer’s reputation. Understanding the nuances of customer experiences and documented case successes allows businesses to make informed decisions and choose manufacturers that align with their quality standards and operational goals.

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

| Manufacturer Location | Customer Satisfaction Rating (out of 5) | Years in Business | Major Industries Served | Notable Case Studies |

|---|---|---|---|---|

| United States | 4.7 | 15 | Automotive, Aerospace | High-Performance Applications |

| Germany | 4.9 | 20 | Pharmaceutical, Manufacturing | Precision Control Solutions |

| Japan | 4.5 | 30 | Electronics, Robotics | Robust Automation Systems |

| China | 4.3 | 10 | Oil & Gas, HVAC | Energy Efficiency Projects |

| Canada | 4.6 | 12 | Mining, Environmental | Sustainable Resource Management |