Top 10 Tips for Choosing the Right Pneumatic Diaphragm Valve for Your Application

When it comes to industrial applications, selecting the right pneumatic diaphragm valve is crucial for ensuring optimal performance, efficiency, and safety. These valves play a significant role in controlling the flow of fluids and gases, making them an integral part of various systems in industries such as chemical processing, pharmaceuticals, and water treatment. However, with a plethora of options available in the market, choosing the appropriate pneumatic diaphragm valve can be a daunting task.

This guide aims to provide you with essential tips on how to select the pneumatic diaphragm valve that best suits your specific application needs. Understanding the operational requirements, material compatibility, and the unique characteristics of various diaphragm valves is vital to making an informed decision. By taking these factors into consideration, you can avoid common pitfalls and ensure that the chosen valve meets the functional demands of your system while also enhancing reliability and longevity. Whether you are a seasoned professional or a newcomer to the field, this outline of key considerations will help streamline your selection process and contribute to the overall success of your project.

Understanding the Functionality of Pneumatic Diaphragm Valves in Systems

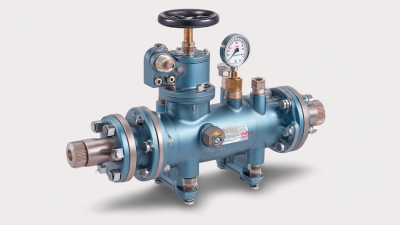

Pneumatic diaphragm valves play a crucial role in various systems, particularly in controlling fluid flow in industries such as water treatment, pharmaceuticals, and food processing. Their design allows for precise regulation of pressure and flow, leveraging the elasticity of the diaphragm, which creates a seal and prevents leakage. According to a recent industry report by MarketsandMarkets, the global diaphragm valve market is expected to grow at a CAGR of 6.5% from 2020 to 2025, reflecting the increasing demand for reliable and efficient valve systems.

When selecting a pneumatic diaphragm valve for your application, it’s important to consider the specific requirements of your system. For instance, factors such as the medium being handled, pressure ratings, and temperature limits can significantly influence performance. One crucial tip is to ensure that the valve materials are compatible with the fluids; for example, high temperatures may require specialized materials to avoid degradation. Additionally, selecting a valve that offers easy maintenance can lead to operational efficiency and reduced downtime.

Another essential consideration is the actuation mechanism. Pneumatic diaphragm valves can be controlled with varying degrees of precision, making it important to match the actuators to your control systems. One tip is to evaluate whether a spring return or double-acting actuator is best suited for your needs, as this can impact response time and reliability in dynamic applications. Understanding these functionalities not only aids in choosing the right valve but also enhances the overall performance of your systems.

Top 10 Tips for Choosing the Right Pneumatic Diaphragm Valve

This chart illustrates the importance of different factors when selecting a pneumatic diaphragm valve for various applications. Each factor is rated on a scale from 1 to 10, with 10 being the most critical. Key considerations include size, material, pressure rating, temperature range, and flow coefficient.

Key Material Considerations for Durability and Performance in Diaphragm Valves

When selecting a pneumatic diaphragm valve, material choice is paramount, as it directly influences both the durability and performance of the valve in various applications. According to a report by the Valve Manufacturers Association (VMA), nearly 30% of valve failures can be attributed to material degradation caused by chemical and thermal stresses. Therefore, understanding the chemical compatibility of materials such as PTFE, EPDM, and NBR is crucial when choosing the right diaphragm. For instance, PTFE is renowned for its exceptional resistance to a wide range of chemicals, making it ideal for corrosive environments. Meanwhile, EPDM offers excellent performance in high-temperature applications, increasing the longevity of the valve in systems that experience significant thermal cycling.

In terms of mechanical properties, the material's tensile strength, elongation, and resilience play critical roles in the valve's ability to withstand varying pressures and operational stresses. The process industry often leverages statistical data from field operations to evaluate the mean time to failure (MTTF) of different materials. Studies indicate that using high-grade elastomers can extend the MTTF of diaphragm valves by up to 25% compared to lower-quality materials. Keeping these factors in mind helps engineers ensure that the selected diaphragm valve not only meets immediate operational needs but also contributes to the overall productivity and reliability of the system.

Evaluating Pressure and Temperature Ratings for Optimal Application Suitability

When selecting a pneumatic diaphragm valve for a specific application, one of the most critical aspects to consider is the pressure and temperature ratings. According to industry reports, valves that do not meet the required operational conditions can lead to failure, resulting in downtime and costly repairs. It’s essential to match the valve specifications with the operational pressure and temperature ranges of your system. For instance, a valve rated for high pressure but used in a low-pressure application might not perform optimally, while using a low-rated valve in high-pressure conditions can lead to catastrophic failures.

To ensure optimal application suitability, first assess the maximum and minimum pressure your system will encounter. According to a study published by the American Society of Mechanical Engineers (ASME), pneumatic systems commonly operate within a standard range of 15 to 150 psi. Valves designed for these conditions will ensure safety and functionality. Additionally, consider the temperature range; to avoid elastomer degradation or metal fatigue, the valve material should match or exceed the operating temperature. Statistical data suggests that nearly 20% of diaphragm valve failures can be attributed to inadequate temperature ratings.

Tip: Always refer to the pressure and temperature charts provided by manufacturers to ensure that you are selecting a valve that aligns with your application's demands. Furthermore, it can be beneficial to consult with a valve specialist who can provide guidance based on your process requirements, ensuring that all parameters are thoroughly evaluated for the most reliable performance.

Top 10 Tips for Choosing the Right Pneumatic Diaphragm Valve for Your Application

| Tip Number | Tip Description | Pressure Rating (psi) | Temperature Rating (°F) | Application Suitability |

|---|---|---|---|---|

| 1 | Evaluate the connection types | 150 | 200 | Water & Wastewater |

| 2 | Consider the diaphragm material | 200 | 180 | Chemical Processing |

| 3 | Assess flow capacity | 250 | 150 | HVAC Systems |

| 4 | Check for compliance standards | 100 | 200 | Food & Beverage |

| 5 | Review actuator options | 300 | 70 | Pharmaceuticals |

| 6 | Determine environmental conditions | 150 | 120 | Oil & Gas |

| 7 | Check for maintenance ease | 100 | 250 | Mining |

| 8 | Consider size and weight restrictions | 200 | 90 | Energy Sector |

| 9 | Evaluate leakage prevention features | 250 | 160 | Marine Applications |

| 10 | Consult with technical experts | 150 | 200 | General Industrial |

Assessing Actuator Specifications for Enhanced Control and Efficiency

When selecting the right pneumatic diaphragm valve for a specific application, understanding the actuator specifications is crucial for achieving enhanced control and efficiency. Actuators play a vital role in how effectively a valve operates. It is essential to consider the actuator's response time and torque requirements to ensure that it can handle the demands of the system. For instance, a higher torque rating may be necessary for systems that require quick opening and closing cycles.

One important tip when assessing actuator specifications is to evaluate the type of actuation required. Different applications may benefit from various actuation methods, such as spring return or double acting. Choosing the right type can significantly influence both the control of the valve and the energy efficiency of the entire system. Additionally, always consider the compatibility of the actuator with the operating environment, ensuring that it can withstand any potential challenges like temperature fluctuations and exposure to corrosive substances.

Moreover, always analyze the control signal input for the actuator. This will ensure that it integrates seamlessly into the existing control system, allowing for precise performance and reliability. Employing actuators with features like feedback mechanisms can further enhance operational efficiency. Properly assessing these actuator specifications not only optimizes the performance of the pneumatic diaphragm valve but also reduces operational costs in the long run.

Importance of Compliance Standards and Certifications in Valve Selection

When selecting a pneumatic diaphragm valve for a specific application, compliance with relevant standards and certifications is paramount. These regulations ensure that the valves meet essential performance and safety criteria, safeguarding both the equipment and the environment. Compliance with industry standards such as those set by the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO) indicates that a valve has undergone rigorous testing and validation processes. This can protect end users from potential failures that might arise from using subpar components.

In addition to ensuring safety and reliability, certifications play a critical role in maintaining regulatory compliance for various industries, including pharmaceuticals, food processing, and chemicals. Valves that meet these stringent requirements not only enhance the integrity of the system but also ease the burden of audits and inspections. By selecting valves that are certified, organizations can foster greater trust among stakeholders and clients, as well as ensure adherence to best practices that can prevent costly downtimes and enhance overall process efficiency.

Related Posts

-

Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

7 Effective Tips to Optimize Pneumatic Flow Valve Performance

-

7 Compelling Reasons to Choose Industrial Control Valves for Your Global Sourcing Needs