Your Comprehensive Guide to Sourcing the Best Pneumatic Solenoid Valves for Your Projects

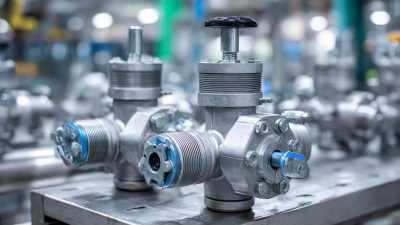

In the world of industrial automation, the choice of components can significantly affect the performance and efficiency of your systems. One of the critical elements in this landscape is the pneumatic solenoid valve, a device that plays a pivotal role in controlling the flow of air and fluids in various applications. Whether you're working on manufacturing processes, robotics, or HVAC systems, selecting the right pneumatic solenoid valve can lead to improved reliability and operational excellence.

This comprehensive guide aims to navigate you through the various considerations and options available in the market, ensuring that you make informed decisions for your projects. From understanding technical specifications to evaluating supplier reliability, we will cover the essential aspects that will help you find the best pneumatic solenoid valve tailored to your needs.

Understanding Pneumatic Solenoid Valves: Key Features and Functionality

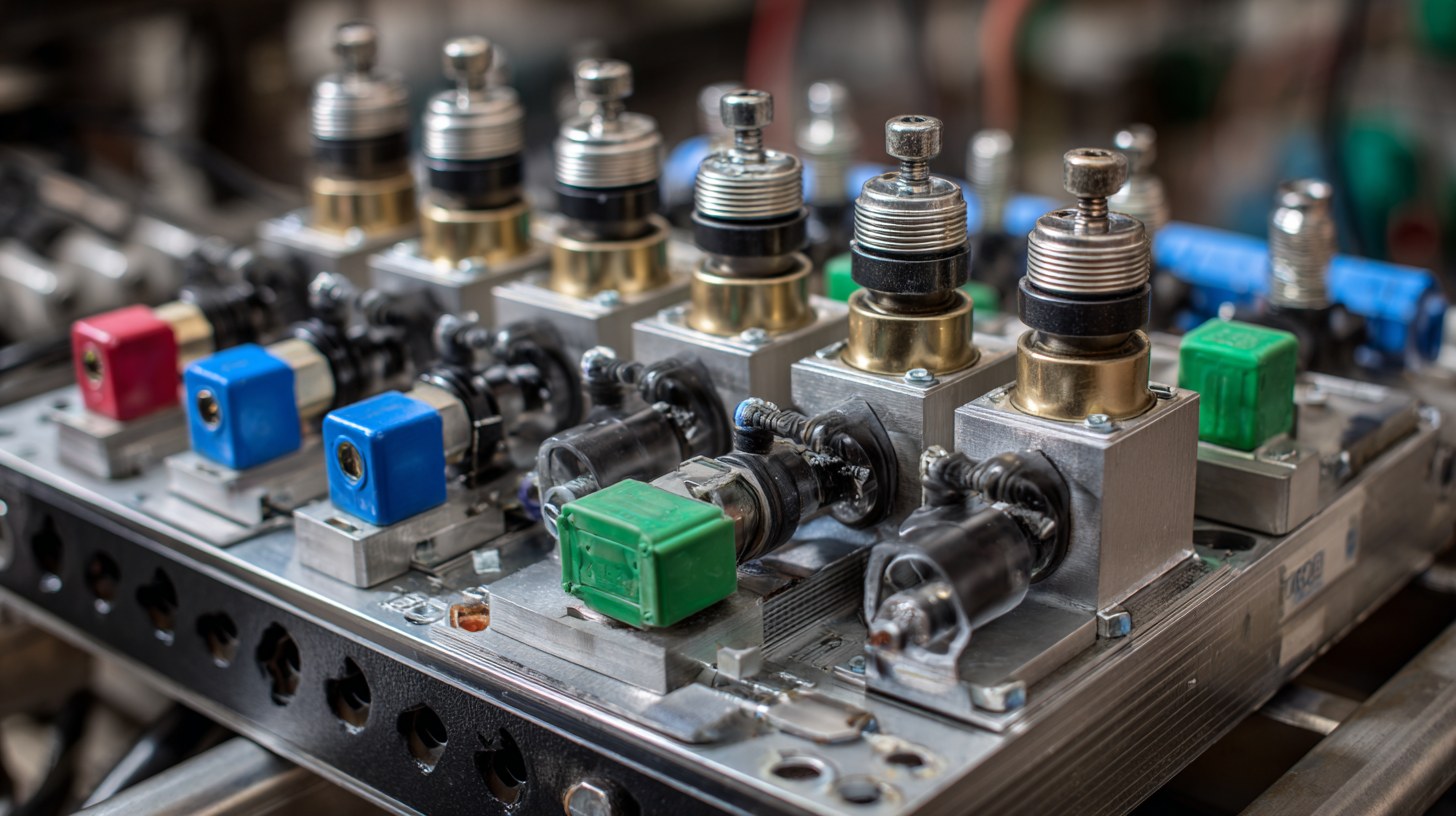

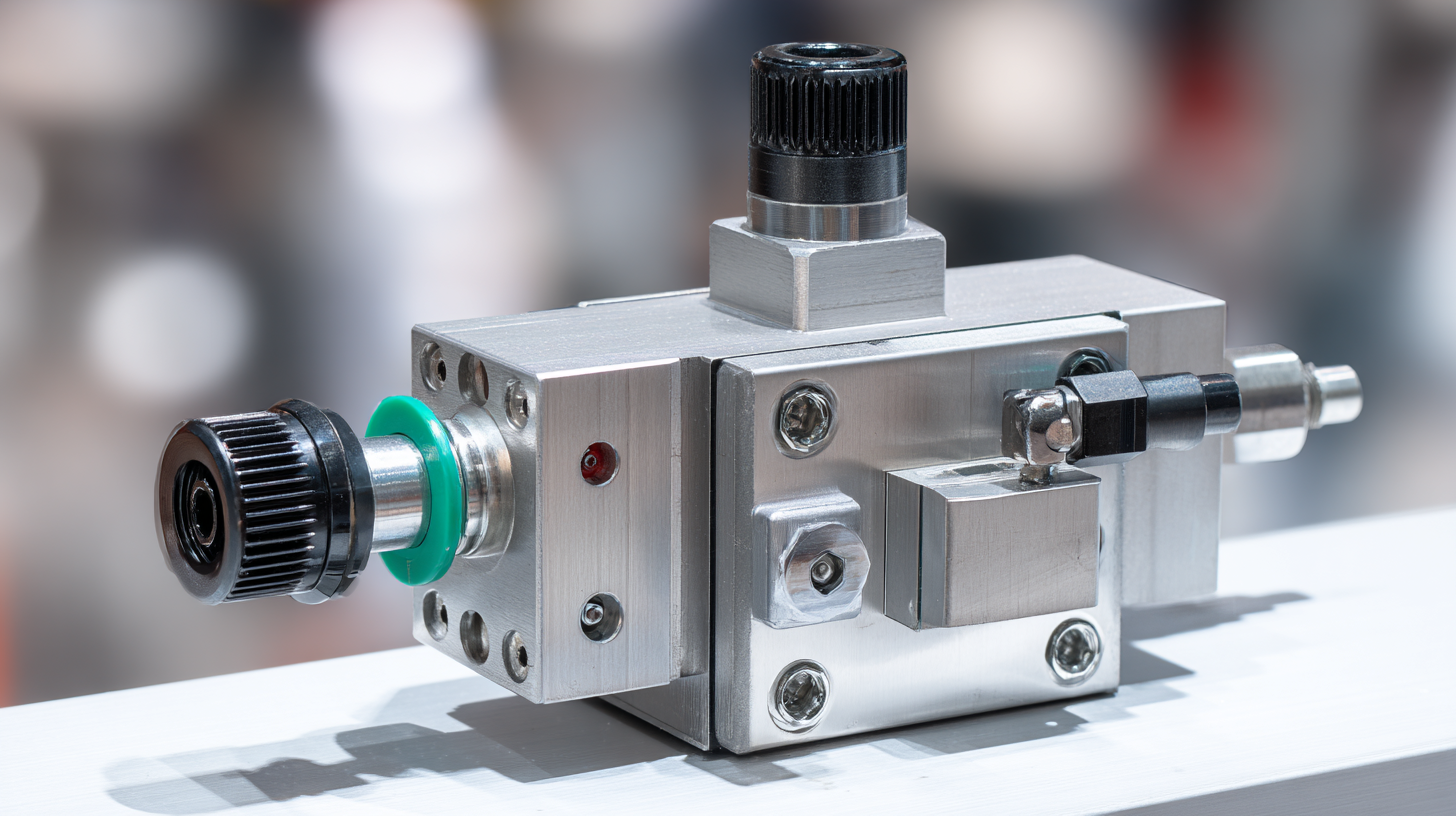

Pneumatic solenoid valves play a crucial role in controlling air flow in various automation projects. Understanding their key features and functionality is essential for selecting the right valve for your application. At the heart of these valves is the solenoid, an electromechanical device that opens or closes the valve in response to an electrical signal. This rapid action allows for efficient control of pneumatic systems, making them ideal for tasks that require precise flow management.

When sourcing pneumatic solenoid valves, consider the valve's size, pressure rating, and material. These factors will determine how well the valve performs under specific conditions. For instance, valves made from corrosion-resistant materials are recommended for environments with harsh chemicals. Additionally, look for valves that offer a range of connectivity options to ensure compatibility with your existing systems.

Tip: Always check the valve's cycle life rating, as it indicates how many operations you can expect before potential failure. This consideration helps you plan for maintenance and replacements, ensuring uninterrupted operation. Furthermore, pay attention to the valve’s response time; a quicker response can enhance the efficiency of your pneumatic automation processes.

Top 5 Considerations for Selecting the Right Pneumatic Solenoid Valve

When sourcing pneumatic solenoid valves for your projects, there are several critical factors to consider to ensure optimal performance and reliability. First and foremost, understanding the specific requirements of your application is crucial. Consider aspects like the operating pressure, fluid type, and temperature range. These parameters directly influence valve selection, as they determine the valve’s compatibility with your system and the conditions it will encounter during operation.

Another significant consideration is the valve configuration. Pneumatic solenoid valves come in various designs, such as 2-way, 3-way, and 5-way options, each serving different purposes in controlling airflow. It’s essential to choose a configuration that aligns with your system's needs. Equally important is the valve’s response time and actuation method. Depending on your application, you may require a valve that reacts quickly to ensure efficiency and performance. Evaluating manufacturers' specifications and, if possible, seeking expert advice can further guide your decision-making process, ensuring you select the best pneumatic solenoid valve tailored to your project's unique demands.

Your Comprehensive Guide to Sourcing the Best Pneumatic Solenoid Valves for Your Projects

3 Common Applications of Pneumatic Solenoid Valves in Various Industries

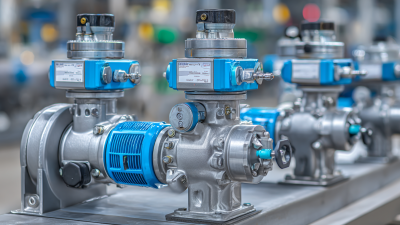

Pneumatic solenoid valves play a pivotal role in various industrial applications, particularly in the realms of automation and control systems. They are commonly employed in industries such as manufacturing, automotive, and food processing. These valves enable precise control over air flow and pressure regulation, essential for efficient operation and energy conservation. According to recent market analysis, the solenoid valve market is anticipated to grow at a CAGR of 3.9%, reaching approximately USD 7,016.7 Million by 2032, indicating a robust demand for these components as industries seek to optimize their processes.

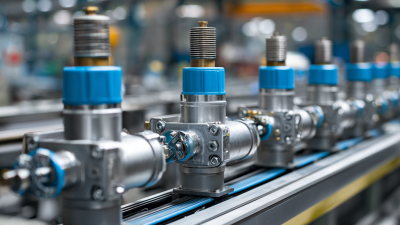

One notable application of pneumatic solenoid valves is in automation systems, where they facilitate quick and reliable actuation of machinery. The evolution of pneumatic technologies, characterized by advancements such as pulsed air systems, has significantly enhanced the efficiency of air consumption, potentially reducing usage by up to 50%. Additionally, the development of modular valve technologies allows for the easy construction of custom valve manifolds, streamlining installation and maintenance in complex automation setups. As the industry progresses towards more energy-efficient solutions, pneumatic solenoid valves will undoubtedly continue to adapt, meeting the stringent performance requirements of modern industrial applications.

Essential Tips for Maintaining Your Pneumatic Solenoid Valves for Longevity

When it comes to the longevity of pneumatic solenoid valves, regular maintenance is key. These components are crucial for the efficient operation of various industrial systems, and neglecting them can lead to performance issues and increased costs. To ensure the longevity of your pneumatic solenoid valves, establish a routine inspection schedule to identify any signs of wear or damage. Additionally, it is essential to keep the valves clean and free from debris that could impede their function. Regular testing of the valves in operation will help determine if they are functioning within the desired parameters.

Recent industry insights emphasize the growing importance of preventative maintenance in the valve market. As businesses strive to reduce downtime and enhance productivity, following best practices for maintaining pneumatic solenoid valves becomes vital. Implementing advanced monitoring solutions can also aid in managing valve operation more effectively. By investing in a proactive maintenance strategy, you will not only increase the lifespan of your pneumatic solenoid valves but also improve the overall efficiency of your industrial processes.

Comparing Top Brands: 4 Must-See Manufacturers of Pneumatic Solenoid Valves

When it comes to pneumatic solenoid valves, choosing from the plethora of available brands can be overwhelming. However, there are four standout manufacturers that consistently deliver reliable products for various applications. Festo, a pioneer in automation technology, is well-known for their high-quality valves that offer exceptional performance and durability. Parker Hannifin, another industry leader, provides a wide range of solutions, catering to both standard and specialized applications, making them a versatile choice for engineers.

Another notable manufacturer is SMC Corporation, recognized for their commitment to innovation and offering products with advanced features. Their pneumatic solenoid valves are designed for efficiency and reliability, allowing for seamless integration into automated systems. Lastly, ASCO, part of the Emerson brand, boasts a strong reputation for producing robust valves suitable for demanding environments. Their extensive line of solenoid valves ensures that there’s a perfect match for every project need.

Tip: When selecting a pneumatic solenoid valve, consider factors such as pressure rating, response time, and environmental conditions. Understanding the specific requirements of your project can help you make a more informed decision. Additionally, always check for certifications and compliance with industry standards to ensure quality and reliability in your applications.

Related Posts

-

Choosing the Right Manufacturer for High Quality Air Solenoid Valve Solutions

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

How to Choose the Best Solenoid Valves for Your Industrial Applications

-

Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

-

Tailored Solutions for Enhancing Efficiency with Advanced Solenoid Valves in Industrial Applications

-

Understanding the Functionality of Diaphragm Flow Control Valves in Modern Applications