Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

The pressure valves industry is on the cusp of significant transformation as we approach 2025, driven by innovations that are reshaping industry standards and applications across various sectors. According to a recent report by MarketsandMarkets, the global pressure relief valve market is projected to reach USD 3.52 billion by 2025, growing at a CAGR of 5.8%. This growth is propelled by the increasing demand for safety applications in industries such as oil and gas, chemical manufacturing, and water treatment.

As technologies evolve, emerging trends in pressure valve design and function, including advanced materials and smart monitoring systems, are setting new benchmarks for performance and reliability. In this blog, we will explore key industry applications of pressure valves and their types, highlighting how these advancements are poised to meet the complexities of modern industrial challenges.

Emerging Innovations in Pressure Valve Design: What to Expect by 2025

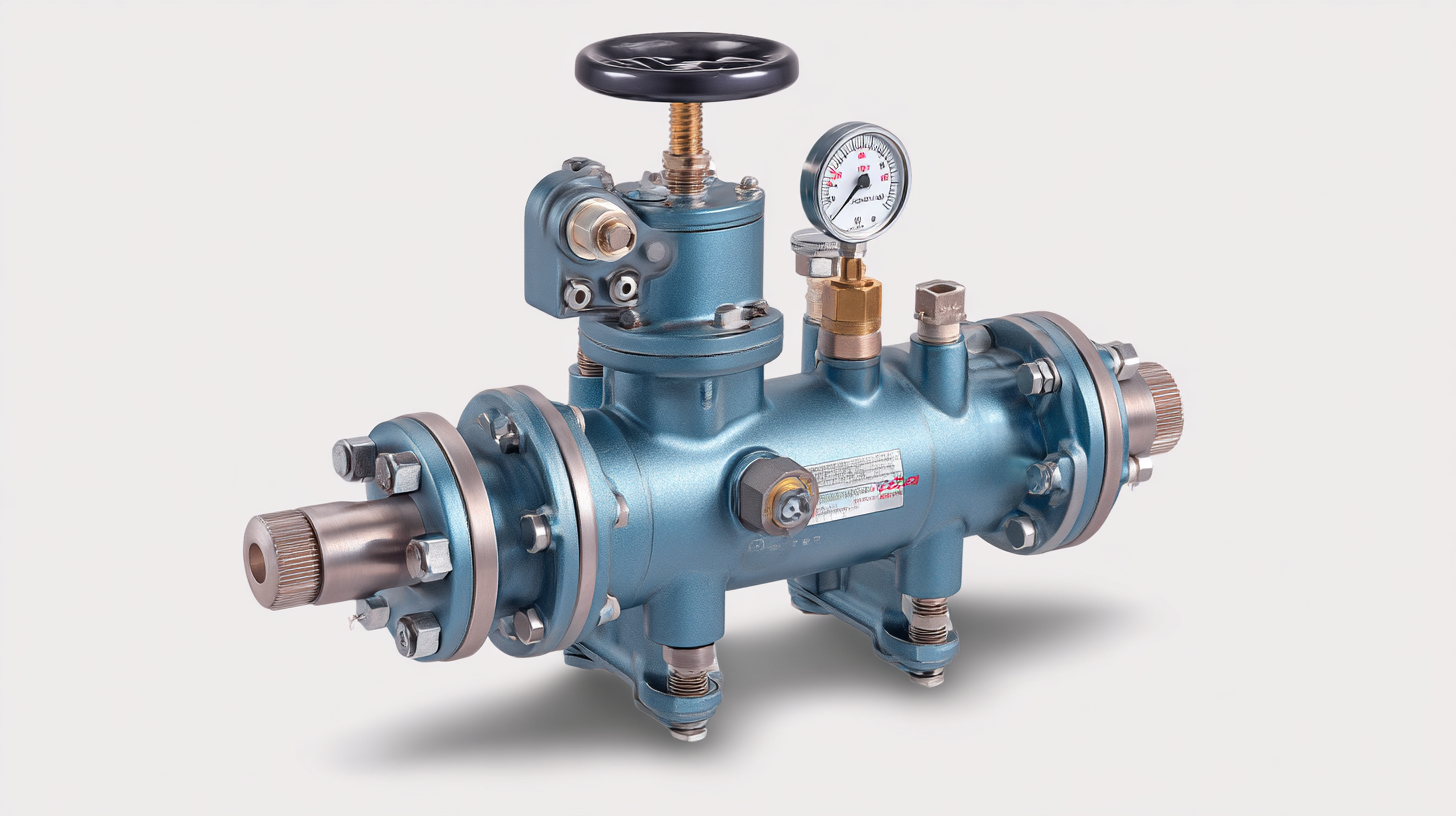

As we approach 2025, the pressure valve industry is on the cusp of groundbreaking innovations that promise to redefine operational efficiency and safety standards. One of the most significant trends is the integration of smart technology into valve design. By embedding IoT (Internet of Things) capabilities, manufacturers are able to offer real-time monitoring and predictive maintenance. This not only enhances system reliability but also reduces operational downtime, allowing industries to optimize their processes.

Another intriguing development is the use of advanced materials in pressure valve construction. Innovations in composites and alloys will result in lighter, more durable designs that can withstand extreme conditions and corrosive environments. These materials not only improve performance but also contribute to sustainability efforts, as manufacturers seek to reduce their carbon footprint. As these trends evolve, we can expect that industry standards will shift dramatically, necessitating upgrades to existing systems and positioning pressure valves as pivotal components in the future of industry technology.

Impact of Digital Transformation on Pressure Valve Technology

The impact of digital transformation on pressure valve technology is becoming increasingly significant, reshaping industry standards and operational efficiencies. According to a recent report by MarketsandMarkets, the global pressure regulator market is projected to reach $12.5 billion by 2025, propelled by advancements in IoT and automation technologies. These digital innovations are enabling real-time monitoring and predictive maintenance, effectively minimizing downtimes and enhancing safety protocols across various sectors including oil and gas, water treatment, and manufacturing.

Moreover, the integration of advanced data analytics in pressure valve systems allows companies to better assess performance and optimize processes. A study by Frost & Sullivan highlighted that organizations leveraging digital technologies can achieve up to a 20% reduction in operational costs. As industries transition towards smart manufacturing practices, the demand for smart pressure valves equipped with sensors and connectivity capabilities is surging. This evolution not only boosts performance and reliability but also supports regulatory compliance, marking a pivotal shift in how pressure valve technology is perceived and utilized in the global marketplace.

Sustainability Practices in Manufacturing Pressure Valves: A 2025 Perspective

As we look toward 2025, the manufacturing of pressure valves is undergoing significant transformation, particularly in the realm of sustainability practices. Companies are increasingly recognizing the importance of sustainable production, not only to comply with regulatory standards but also to address the growing demand for eco-friendly products.

Innovations in materials, such as the use of recycled metals and biodegradable components, are becoming mainstream, allowing manufacturers to reduce their carbon footprint while still maintaining high-quality production standards.

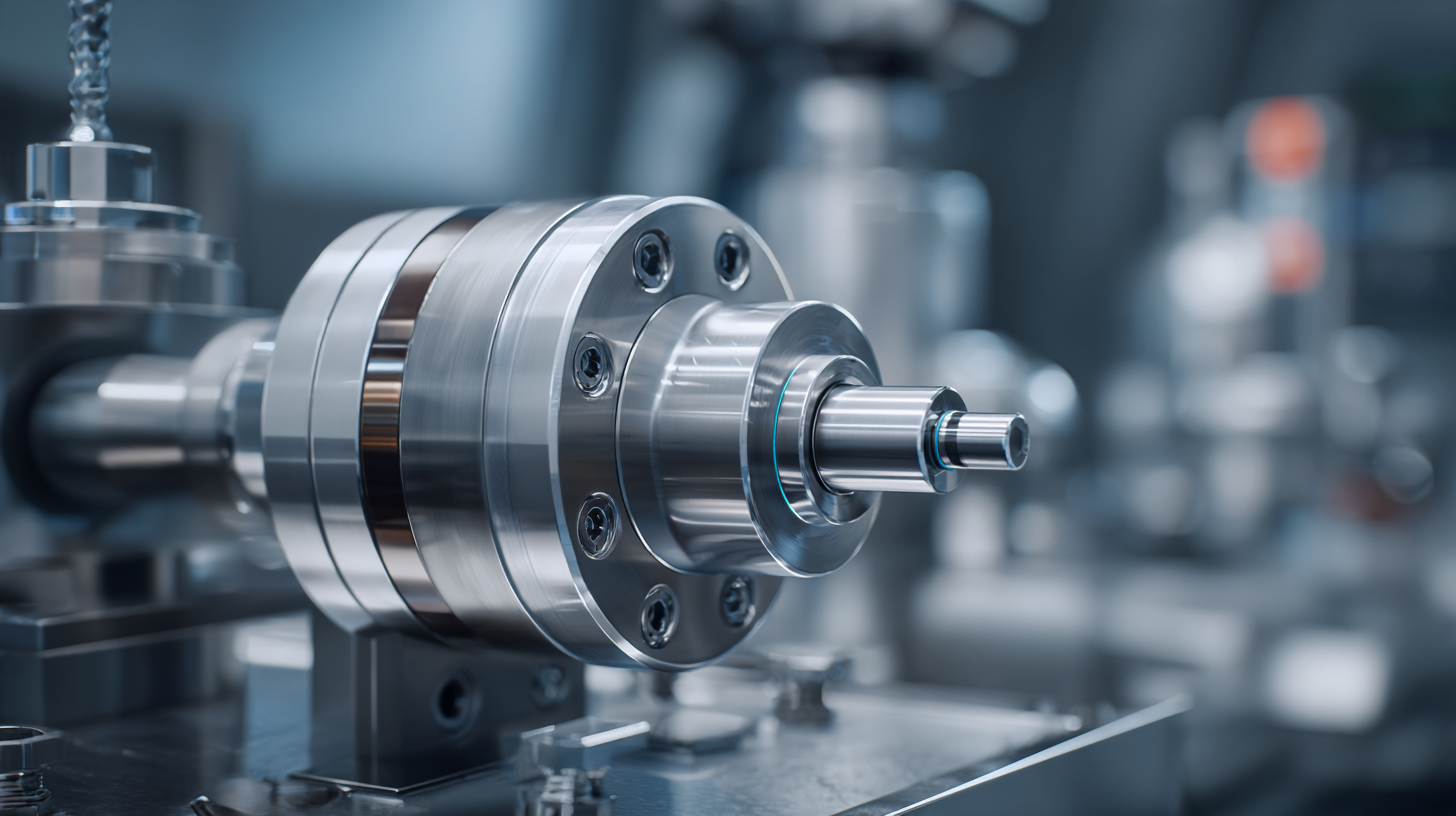

Moreover, advancements in technology are enabling more efficient manufacturing processes. Techniques such as additive manufacturing (3D printing) are being adopted to minimize waste and optimize resource usage. This shift not only streamlines production timelines but also supports the creation of custom pressure valves that meet specific client demands without the excess associated with traditional methods. By integrating sustainability into their core operations, manufacturers are not only contributing to environmental conservation but are also positioning themselves as leaders in an evolving market, where sustainable practices will soon become a benchmark for industry standards.

Evaluating the Role of Automation in Pressure Valve Production

The landscape of pressure valve production is rapidly transforming, driven predominantly by the integration of automation technology. As industries strive for efficiency and precision, automation has emerged as a pivotal force in refining production processes. The adoption of robotics and advanced manufacturing techniques allows for enhanced workflow, reducing manual labor and minimizing human error. This transition not only boosts productivity but also ensures consistent quality in valve manufacturing, setting a new benchmark for industry standards.

Moreover, the role of automation extends beyond mere production efficiency. Smart pressure valves equipped with IoT sensors enable real-time monitoring and data collection, facilitating predictive maintenance and proactive decision-making. This interconnectivity not only enhances operational insights but also contributes to longer product lifespans and reduced downtime. As companies increasingly recognize the value of these innovations, the evolution of pressure valve technology in 2025 will likely be characterized by an emphasis on smart manufacturing and sustainability, ultimately reshaping industry practices for years to come.

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards - Evaluating the Role of Automation in Pressure Valve Production

| Trend | Impact on Industry | Automation Role | Expected Benefits |

|---|---|---|---|

| Smart Pressure Valves | Increase efficiency and safety in operations | Utilizing real-time monitoring and data analysis | Reduced downtime and improved maintenance practices |

| IoT Integration | Enhanced connectivity across systems | Automation of data collection and reporting | Better decision-making and streamlined operations |

| Advanced Materials | Improved durability and performance | Automated quality control systems in production | Longer lifespan and reduced replacement costs |

| Increased Customization | Meeting specific customer needs more effectively | Flexible manufacturing processes powered by automation | Enhanced customer satisfaction and loyalty |

| Regulatory Compliance Automation | Streamlined adherence to safety and quality standards | Automated documentation and reporting systems | Reduced risk of non-compliance and penalties |

Global Standards and Regulations Shaping the Future of Pressure Valves

The landscape of pressure valve technology is evolving rapidly as manufacturers adapt to new global standards and regulations. As highlighted by forecasts, the pressure safety valve market is expected to grow significantly, reaching USD 6.94 billion by 2034. This growth is driven not only by increasing demand for safety valves but also by the need for compliance with updated regulations that aim to ensure operational safety across various industries. The adoption of innovative designs and materials in valve technology is essential for meeting these evolving standards, thereby enhancing efficiency and reliability in diverse applications.

As sectors such as HVAC transition to new refrigerants, the implications for pressure valve markets are profound. The American Innovation and Manufacturing Act of 2020 catalyzes this transition, setting the stage for manufacturers to innovate in valve technologies that can accommodate these changes. The commitment to reducing environmental impact while maintaining system integrity is driving valve manufacturers to develop solutions that align with both regulatory requirements and market demands. As industries continue to prioritize safety and sustainability, the integration of advanced pressure valve technologies will play a crucial role in shaping the future of global standards.