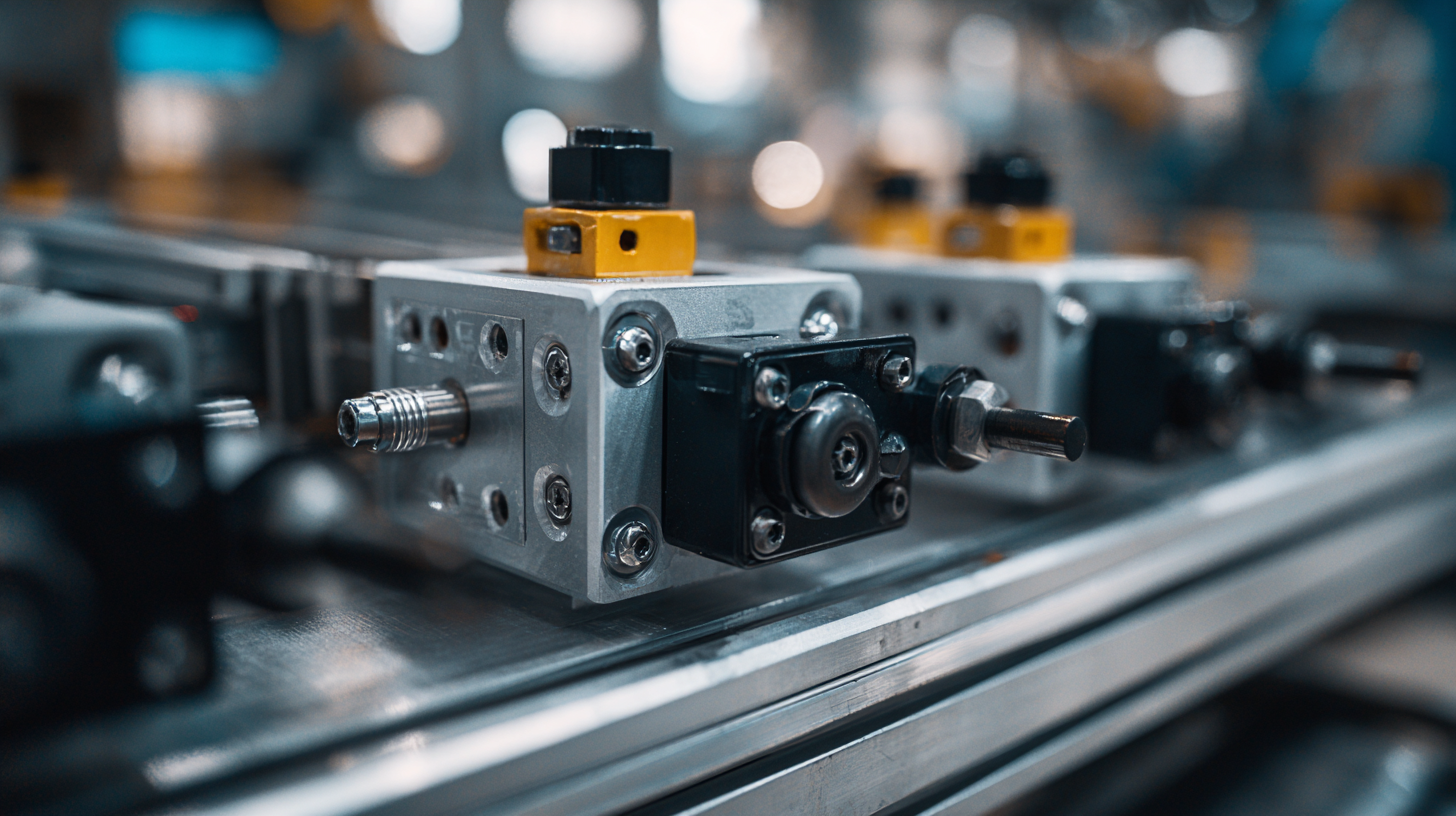

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

In the rapidly evolving landscape of industrial automation, the significance of small pneumatic valves cannot be overstated. According to a report by MarketsandMarkets, the global pneumatic valve market is projected to reach $9.18 billion by 2025, with a significant contribution from small pneumatic valves due to their compact design and efficiency in applications ranging from manufacturing to food processing. As industries continually seek to enhance operational efficiency and reduce space constraints, innovative alternatives to traditional small pneumatic valves have emerged as essential components in fluid control systems. This blog explores various innovative alternatives and their potential benefits, aiming to equip industry professionals with the knowledge needed to make informed choices that align with their operational needs.

Challenges in Identifying the Right Small Pneumatic Valves for Automation Processes

Identifying the right small pneumatic valves for automation processes can be a complex challenge for many industries. As manufacturers continue to strive for greater efficiency and precision, the demand for advanced valve systems is rising. According to a recent industry report, the global pneumatic valve market is projected to reach $7.4 billion by 2026, with a compound annual growth rate (CAGR) of 6.5%. This growth is driven largely by the automation sector, where the need for reliable components is paramount.

Moreover, the integration of AI into manufacturing processes may offer innovative solutions to the challenges faced in selecting the right pneumatic valves. As AI systems become more capable of analyzing operational data and optimizing workflows, they could assist technicians in determining the most effective valve configurations tailored to specific automation needs. This technological evolution not only promises to enhance the operational efficiency but also supports the growing trend of customization in manufacturing, particularly in industries like cannabis beverage production, where standardization plays a crucial role in ensuring quality and compliance.

Evaluating the Limitations of Traditional Pneumatic Valves in Industrial Applications

As industries increasingly rely on pneumatic systems for automation, the limitations of traditional pneumatic valves have come into sharp focus. Traditional valves often suffer from issues like slow response times and overshoot, which can lead to inefficient processes and increased operational costs. Recent studies show that incorporating advanced control strategies, such as fractional-order proportional-integral-derivative (FOPID) controllers, can significantly improve the performance of pneumatic control valves. These systems can achieve ultra-low overshoot and rapid response times, enhancing the robustness of control in various industrial applications.

Beyond performance, traditional pneumatic valves also face challenges in energy efficiency, especially in energy-intensive environments like cooling and air-conditioning systems for buildings. Reports indicate that HVAC systems can account for up to 60% of a building's total energy consumption in hot climates, underscoring the need for innovative alternatives. By exploring new technologies and integrating energy-efficient components into pneumatic systems, industries can address both performance limitations and sustainability objectives. The evolution of these systems is critical as organizations strive to optimize energy consumption while maintaining high operational efficiency.

Cost Analysis: The Economic Impact of Switching to Innovative Alternatives

Switching to innovative alternatives for small pneumatic valves can significantly influence the economic landscape of industrial operations. According to a study by the Industry Research Institute, companies that have transitioned to advanced valve technology report a cost reduction of up to 30% in maintenance expenditures. These savings accrue from enhanced durability and efficiency, reducing the frequency of replacements and downtime.

Furthermore, manufacturers are discovering that integrating smart valve systems can yield an additional 15% in efficiency gains, directly impacting production costs.

Tips for making the transition effectively include conducting a thorough cost-benefit analysis. Prioritize data collection on current expenditures related to traditional pneumatic valves and compare them against potential investments in innovative technologies. Engaging with suppliers to obtain trial units can also provide valuable insights without significant upfront commitment.

Moreover, consider the scalability of new valve solutions. As noted in the annual report by the Fluid Power Manufacturers Association (FPMA), scalability can enhance operational flexibility, adapting to changing production needs without incurring substantial additional costs. By focusing on both immediate and long-term economic impacts, industries can make informed decisions that foster sustainable growth while optimizing their pneumatic systems.

Compatibility Issues: How Material Selection Affects Pneumatic Valve Performance

When selecting pneumatic valves for industrial applications, material compatibility is a critical factor that can significantly influence performance and longevity. For instance, recent studies have shown that the choice of materials can impact seal integrity and corrosion resistance, which are essential for ensuring efficient operation. According to industry reports, over 30% of pneumatic system failures are attributed to material incompatibility, highlighting the importance of selecting the right materials to match the operating environment.

Moreover, the performance of pneumatic valves can vary widely based on temperature and pressure conditions, with certain materials performing better in high-temperature settings. Research indicates that using materials with high thermal stability, such as specific polymers or advanced alloys, can enhance valve lifespan and reduce maintenance costs. A modeling study focusing on pneumatic devices revealed that proper material selection could improve efficiency by up to 20%, emphasizing the value of thorough material evaluation during the design process. As industries continue to prioritize sustainability and efficiency, understanding these compatibility issues becomes paramount for optimizing pneumatic system performance.

Material Selection and Its Impact on Pneumatic Valve Performance

Trends in the Small Pneumatic Valve Market: Innovations Shaping the Future

The small pneumatic valve market is undergoing significant transformations, driven by innovations that enhance efficiency and precision in industrial applications. As industries increasingly prioritize automation and sustainability, manufacturers are investing in smart valve technology that integrates IoT capabilities. This shift not only improves real-time monitoring but also aids in predictive maintenance, reducing downtime and operational costs.

When exploring alternatives to traditional pneumatic valves, consider investing in valves that offer modular designs. These designs allow for easy customization and scalability, making them suitable for various applications without extensive modifications. Additionally, look for products that utilize new materials, such as lightweight and corrosion-resistant composites, which enhance durability and reduce the environmental footprint.

Tips for choosing the right small pneumatic valve include assessing compatibility with your existing systems and reviewing performance metrics in terms of flow rates and pressure drop. Ensure to evaluate the supplier's customer service and technical support, as these factors can significantly impact your operational efficiency. Embracing these innovative options will not only streamline processes but also align with future trends in industrial automation.