Mastering Pneumatic Flow Control Valves A Comprehensive Guide for Global Buyers

In an era where automation and efficiency are paramount, the significance of pneumatic flow control valves has escalated dramatically across various industries. According to a report by ResearchAndMarkets, the global pneumatic valve market is projected to reach USD 9.50 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. This growth is driven by the increasing demand for energy-efficient systems and the automation of industrial processes.

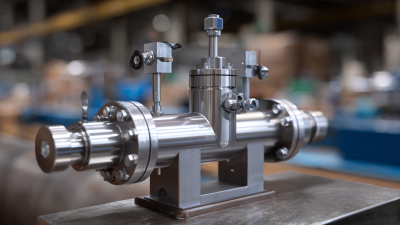

Mastering pneumatic flow control valves is essential for global buyers who aim to optimize their operations. These valves play a crucial role in regulating the flow and pressure of compressed air within pneumatic systems, thus enhancing overall performance and reliability. This comprehensive guide will equip buyers with the necessary knowledge to navigate the complexities of selecting and utilizing pneumatic flow control valves effectively.

Mastering pneumatic flow control valves is essential for global buyers who aim to optimize their operations. These valves play a crucial role in regulating the flow and pressure of compressed air within pneumatic systems, thus enhancing overall performance and reliability. This comprehensive guide will equip buyers with the necessary knowledge to navigate the complexities of selecting and utilizing pneumatic flow control valves effectively.

Identifying Common Issues in Pneumatic Flow Control Valves

Pneumatic flow control valves play a crucial role in the efficiency and

performance of various systems, but they are not without their challenges. Common issues can arise from wear and tear, leading to performance degradation

such as inconsistent flow rates, leakage, and excessive pressure drops. These problems can

significantly affect operational efficiency, particularly in high-flow rate applications where energy consumption

is a critical concern. Identifying these issues early can save businesses substantial costs and enhance system reliability.

Pneumatic flow control valves play a crucial role in the efficiency and

performance of various systems, but they are not without their challenges. Common issues can arise from wear and tear, leading to performance degradation

such as inconsistent flow rates, leakage, and excessive pressure drops. These problems can

significantly affect operational efficiency, particularly in high-flow rate applications where energy consumption

is a critical concern. Identifying these issues early can save businesses substantial costs and enhance system reliability.

As pneumatic systems age, alternative designs and monitoring solutions have emerged to mitigate these common pitfalls. For instance, integrating

predictive maintenance techniques can help in fault detection and isolation, allowing operators to address issues proactively.

This approach not only reduces downtime but also ensures energy efficiency by

minimizing unnecessary throttling and pressure drops. Ongoing advancements in valve technology and design are essential for global buyers

to consider, ensuring that they remain ahead of the curve in performance and sustainability.

Understanding the Impact of Valve Types on Performance

When it comes to pneumatic flow control valves, understanding the various types and their impact on performance is crucial for global buyers seeking optimized solutions for their systems. Different valve types, such as needle valves, ball valves, and proportional valves, present distinct characteristics that influence flow rate, pressure regulation, and system efficiency. For instance, needle valves allow for fine adjustments in flow, making them ideal for applications requiring precise control, while ball valves offer quick shut-off capabilities that can enhance system responsiveness.

Moreover, the selection of a valve type can profoundly affect the overall operational efficiency of pneumatic systems. Choosing the wrong valve could lead to issues such as excessive energy consumption, slow response times, or inadequate system pressure. Buyers need to consider their specific application requirements, including the range of pressure, desired flow rate, and environmental conditions. By taking the time to understand how different valve types impact performance, companies can make informed decisions that lead to improved productivity and reduced operational costs in their pneumatic systems.

Performance Comparison of Pneumatic Flow Control Valve Types

This chart illustrates the flow rates of various pneumatic flow control valve types, providing valuable insights for buyers seeking to understand how different valve types affect performance.

Troubleshooting Tips for Common Pneumatic Valve Problems

When it comes to pneumatic flow control valves, troubleshooting common issues can save time and enhance efficiency. One significant problem often encountered is a decrease in airflow, which may be caused by a clogged filter or a malfunctioning diaphragm. Regular maintenance and inspection of these components are essential. **Tip:** Always clean or replace filters regularly to prevent clogs, ensuring smooth operation and optimal airflow.

Another frequent challenge is valve leakage, which can occur due to worn seals or misalignment. Detecting the source of a leak promptly is vital to maintaining system integrity. **Tip:** Applying a soapy water solution to suspect areas can help identify leaks, allowing for quick repairs before they escalate into more significant issues. By addressing these common problems and implementing these simple tips, users can master pneumatic flow control valves and enhance the reliability of their systems.

Maintenance Practices to Ensure Optimal Flow Control

Maintaining pneumatic flow control valves is essential for achieving optimal performance and efficiency in various industrial applications. Regular maintenance practices—such as inspections, cleaning, and timely replacement of worn components—are vital to prevent flow disruptions and ensure the longevity of the system. This aligns with the broader trends in energy infrastructure management, where the integration of real-time monitoring technologies plays a crucial role in enhancing system resilience and operational effectiveness. By employing advanced digital tools, manufacturers can detect potential issues early and optimize maintenance schedules based on actual performance metrics.

Moreover, the maintenance of these valves contributes to a more sustainable operation by minimizing leaks and improving the overall flow control in systems, such as hydropower facilities. Recent studies highlight the importance of adopting data-driven maintenance strategies that leverage AI and machine learning for predictive analysis. This proactive approach not only enhances operational reliability but also supports environmental goals by reducing energy waste and promoting the efficient use of resources. As industries increasingly focus on digitalization and automation, maintaining pneumatic flow control valves with best practices has become a critical component of comprehensive system management.

Analyzing the Cost of Ignoring Flow Control Valve Issues

Ignoring issues related to flow control valves can lead to significant operational challenges and increased costs for businesses. Flawed or malfunctioning valves can disrupt fluid dynamics, leading to inefficiencies and even catastrophic failures in systems. To illustrate, recent research into the dynamic modeling of high-pressure regulators emphasizes the importance of maintaining precise control over outlet pressures. Such insights reinforce that addressing flow control valve issues proactively is essential for ensuring reliability in high-stakes environments, like hydrogen refueling stations.

Tips for maintaining flow control valves include regular inspections and employing advanced modeling techniques to predict potential failures before they occur. Ensure that your maintenance team is trained to identify common cavitation phenomena, which can seriously affect valve performance, particularly in multi-port structures like three-way globe valves. Additionally, investing in numerical analysis tools can provide deeper insights into the thermal characteristics of valves, allowing for more effective troubleshooting and preventative measures. By prioritizing flow control valve management, businesses can avoid costly downtime and enhance overall system efficiency.

Related Posts

-

2025 Market Trends in Pneumatic Valves for Global Buyers

-

Exploring Innovative Alternatives to the Best Small Pneumatic Valves for Your Industrial Needs

-

The Definitive Guide to Sourcing Top Quality Small Pneumatic Valves from Trusted Suppliers

-

7 Effective Tips to Optimize Pneumatic Flow Valve Performance

-

7 Essential Features of Small Pneumatic Valves You Should Know About

-

Unlocking Precision in Fluid Dynamics with the Best Liquid Flow Control Valve Technical Specifications and Best Practices