Why Choose a Proportional Flow Control Valve for Optimal System Performance

In the realm of hydraulic and pneumatic systems, achieving optimal performance is crucial for enhancing operational efficiency and reliability. A key component in regulating fluid flow within these systems is the proportional flow control valve. This advanced technology enables precise control over flow rates, allowing for the fine-tuning of system dynamics to match operational requirements. Unlike traditional flow control valves, the proportional flow control valve adjusts flow based on input signals, offering a responsive solution that adapts to varying system demands.

The integration of a proportional flow control valve not only enhances performance but also contributes to energy savings and reduced wear on system components. By allowing for smoother transitions and maintaining consistent flow rates, these valves minimize the risk of pressure spikes and fluctuations, which are often detrimental to system longevity. Furthermore, their ability to provide accurate and real-time adjustments ensures that systems operate within their optimal parameters, leading to improved productivity and reduced operational costs.

In summary, choosing a proportional flow control valve is a strategic decision for anyone seeking to enhance the performance and reliability of hydraulic and pneumatic systems. Its ability to deliver precise flow regulation and responsiveness makes it an indispensable tool in modern fluid control applications.

Understanding Proportional Flow Control Valves and Their Functionality

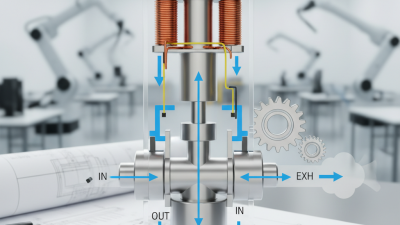

Proportional flow control valves are integral components in hydraulic and pneumatic systems, serving the essential purpose of regulating fluid flow in a controlled manner. Unlike traditional on-off valves, these valves allow for precise adjustments to the flow rate, leading to enhanced system performance and efficiency. They often employ electronic controls, enabling real-time modulation based on the system's requirements, which is crucial for applications where exact flow rates are necessary for optimal operation.

The functionality of proportional flow control valves is rooted in their ability to respond dynamically to varying system pressures and demands. By utilizing feedback mechanisms, these valves adjust the opening size to maintain the desired flow rate, regardless of external fluctuations. This capability not only improves energy efficiency but also prolongs the lifespan of the system by reducing wear and tear on components. As a result, integrating proportional flow control valves can significantly enhance the overall reliability and performance of a hydraulic or pneumatic system.

Understanding Proportional Flow Control Valves and Their Functionality

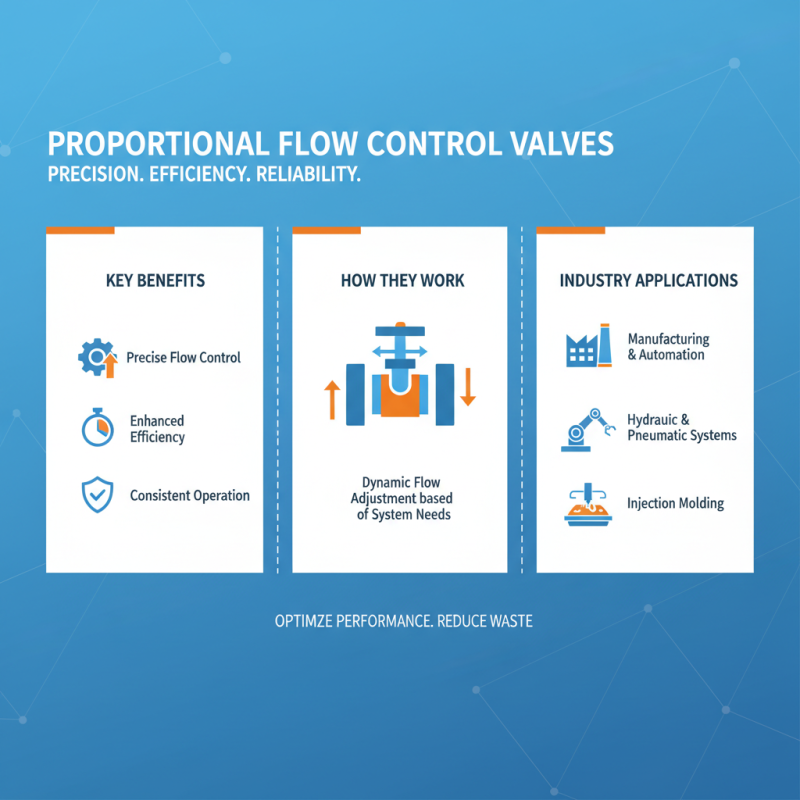

Key Advantages of Using Proportional Flow Control Valves in Systems

Proportional flow control valves are increasingly recognized for their ability to enhance system performance across various applications. One of the key advantages of these valves is their precise control over flow rates. By allowing for real-time adjustments, proportional flow control valves enable systems to operate at optimal efficiency, reducing energy consumption while maintaining required performance levels. This flexibility is particularly beneficial in dynamic environments where demand can change rapidly, allowing for seamless adaptation to varying operational needs.

**Tip:** When selecting a proportional flow control valve, consider the specific requirements of your system, including flow rate, response time, and pressure conditions. This will ensure that the valve you choose maximizes efficiency and extends the lifespan of your equipment.

Another significant advantage of using proportional flow control valves is their ability to minimize wear and strain on system components. Traditional on/off valves can lead to abrupt changes in pressure and flow, contributing to system fatigue. In contrast, proportional valves offer smoother transitions, which can greatly reduce mechanical stress and prolong the life of both the valve and the entire system. This not only lowers maintenance costs but also enhances reliability and performance in the long run.

**Tip:** Regularly monitor the performance of your proportional flow control valves to identify any changes in their operation. Early detection of issues can help prevent costly downtimes and ensure the efficient functioning of your system.

Why Choose a Proportional Flow Control Valve for Optimal System Performance

| Feature | Description | Benefit |

|---|---|---|

| Precision Control | Allows for fine-tuning of flow rates in various applications. | Enhances system efficiency and reduces energy costs. |

| Responsive Operation | Quick response time to changes in system demand. | Improves process stability and product quality. |

| Versatility | Can be used in various applications like hydraulic and pneumatic systems. | Reduces the need for multiple types of valves. |

| Durability | Constructed of high-quality materials designed for long life. | Reduces maintenance costs and downtime. |

| Integration | Easily integrates with electronic controls and automation systems. | Enhances overall system functionality and control. |

Applications of Proportional Flow Control Valves Across Industries

Proportional flow control valves have become essential components in various industries due to their ability to provide precise control over fluid flow rates. In the manufacturing sector, these valves are extensively used in hydraulic and pneumatic systems to achieve consistent and reliable operation. By allowing operators to adjust flow rates dynamically, proportional flow control valves enhance efficiency and ensure that machinery functions optimally under varying loads and conditions. This flexibility is particularly valuable in applications like injection molding, where maintaining the correct material flow is critical for product quality.

In the realm of automotive manufacturing, proportional flow control valves play a key role in enhancing vehicle performance. They manage the flow of fluids in systems like steering and brake circuits, thereby improving responsiveness and safety. Similarly, in agricultural applications, these valves are utilized in precision irrigation systems, enabling farmers to control water flow efficiently and sustainably. This not only conserves resources but also maximizes crop yield by delivering the right amount of moisture precisely when needed.

**Tips:** When selecting a proportional flow control valve, consider the specific flow requirements and system compatibility to ensure optimal performance. Regular maintenance and calibration are essential to sustain the efficiency and accuracy of these valves in real-world applications. Additionally, always consult with professionals to tailor solutions suited to your operational needs for enhanced productivity.

Comparing Proportional Flow Control Valves to Other Flow Control Devices

When evaluating flow control devices for optimal system performance, proportional flow control valves stand out due to their ability to provide precise control over fluid flow. Unlike traditional on-off valves or simple throttling devices, proportional valves modulate flow in response to electrical signals, allowing for enhanced responsiveness and adaptability within hydraulic and pneumatic systems. This capability translates to smoother operation, improved efficiency, and better overall performance, particularly in applications that require varied flow rates based on system demands.

In comparison to fixed flow control devices, proportional flow control valves offer significant advantages. Fixed devices can limit performance by providing only a single flow rate, which may not adequately meet fluctuating operational requirements. Additionally, while simple pressure relief valves can prevent system overload, they may not offer the nuanced control that proportional valves provide. This flexibility allows for dynamic adjustment, resulting in energy savings and reduced wear on system components. Thus, for applications where precision and adaptability are paramount, proportional flow control valves are often the superior choice.

Best Practices for Selecting and Implementing Proportional Flow Control Valves

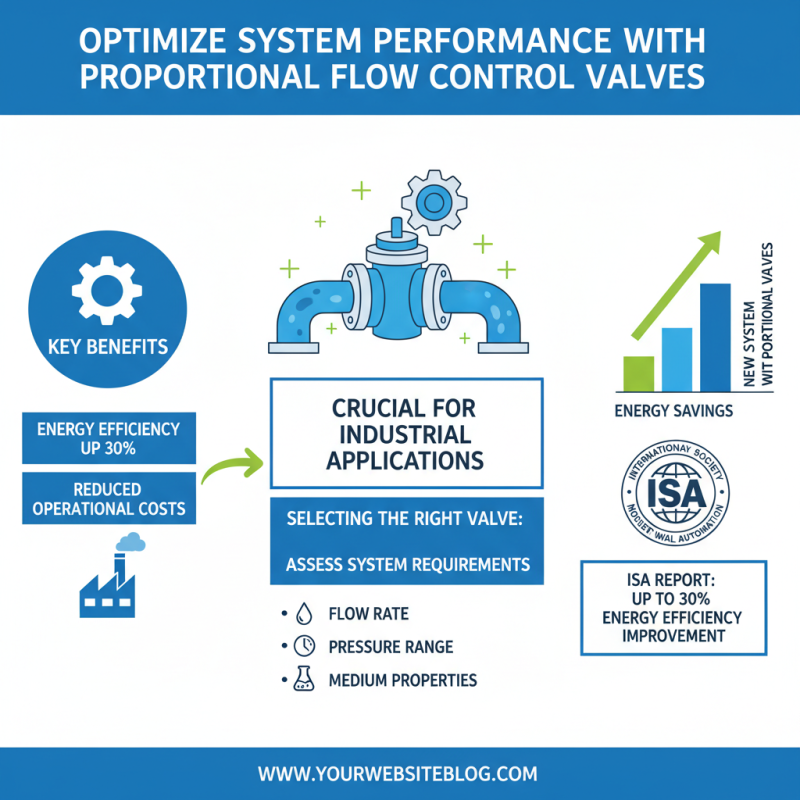

When it comes to enhancing system performance, selecting and implementing proportional flow control valves is crucial for various industrial applications. According to a report by the International Society of Automation, the use of proportional flow control valves can improve energy efficiency by up to 30%, significantly reducing operational costs. Therefore, understanding the specific requirements of your system is essential. Factors such as flow rate, pressure range, and medium properties should be carefully assessed to ensure the chosen valve meets the operational demands.

Best practices for selecting proportional flow control valves include thorough system analysis and simulation. Engineers should utilize computational fluid dynamics (CFD) modeling to predict how flow characteristics will change under different operating conditions. The use of advanced simulation techniques can lead to a more informed decision, minimizing issues such as cavitation or noise, which can adversely affect system performance. Furthermore, regular maintenance and calibration are necessary to sustain optimal functionality, as neglecting these practices can result in decreased responsiveness and efficiency over time. Adopting these strategies ensures the reliability and longevity of flow control systems, ultimately leading to better overall system performance and productivity.

Related Posts

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

Mastering Pneumatic Flow Control Valves A Comprehensive Guide for Global Buyers

-

Exploring Proportional Flow Control Valve Innovations at the 138th Canton Fair 2025 in China

-

Innovative Air Flow Valve Solutions for Enhanced Performance and Efficiency

-

7 Essential Features of Small Pneumatic Valves You Should Know About

-

What is a Pneumatic Solenoid Valve and How Does It Work