Top 10 Control Valves for Efficient Fluid Management in Industrial Applications

In today's rapidly evolving industrial landscape, the importance of effective fluid management cannot be overstated. Control valves play a critical role in regulating flow, pressure, and temperature within various systems, thereby ensuring operational efficiency and safety. According to Dr. Emily Carter, a prominent expert in the control valves industry, "Control valves are the heartbeat of any fluid management system, providing the necessary control mechanisms to optimize processes and conserve resources."

As industries demand greater efficiency and sustainability, the selection of the right control valves becomes paramount. With a myriad of options available, understanding the characteristics and functionalities of these valves is essential for making informed decisions. This article delves into the top 10 control valves that are crucial for achieving efficient fluid management across industrial applications. From globe valves to ball valves, we will explore their unique attributes, advantages, and the role they play in enhancing system performance, ultimately contributing to a more efficient future in fluid management.

Overview of Control Valves in Industrial Fluid Management

Control valves play a crucial role in the efficient management of fluids in industrial settings. They regulate flow, pressure, and temperature, ensuring optimal performance of equipment and processes. By responding to signals from control systems, these valves help maintain desired operating conditions, minimize energy consumption, and enhance safety. The right selection of control valves can lead to significant improvements in productivity and operational efficiency, making them indispensable in various industries such as oil and gas, water treatment, and chemical manufacturing.

Tips for selecting the appropriate control valve include considering the specific application requirements, such as the type of fluid, temperature, pressure, and flow rate. Additionally, understanding the valve characteristics—like flow coefficient and actuator type—can aid in making informed decisions. Proper installation and maintenance practices are essential to ensure the longevity and reliability of control valves. Regular inspection can prevent leaks and failures, ultimately contributing to a more efficient fluid management system.

Another important aspect is to prioritize the use of materials that are compatible with the fluid being handled. Selecting valves constructed from the right materials helps prevent corrosion and wear, leading to enhanced performance and reduced downtime. Implementing automation in the control valve operation can also optimize fluid management by providing real-time monitoring and adjustments, further improving system efficiency.

Criteria for Selecting the Most Efficient Control Valves

When selecting the most efficient control valves for industrial applications, several criteria must be carefully considered to ensure optimal fluid management. First, the valve's flow characteristics are crucial; it should provide precise control over the flow rates to meet the specific requirements of the system. A valve with a linear, equal percentage, or quick opening characteristic can significantly influence process efficiency, allowing for better responsiveness to varying operational conditions.

Another important aspect is the valve material and construction. The materials must be compatible with the fluids being managed, as this will affect corrosion resistance, durability, and operational life. Additionally, factors such as the size of the valve, its pressure rating, and temperature limits should align with system specifications to prevent failures during operation. It is also essential to evaluate the valve's actuator type—whether manual, pneumatic, or electric—to ensure it meets the control requirements while providing reliability and ease of maintenance.

Finally, consider the valve's ability to integrate with existing automation systems. Features such as communication protocols and feedback mechanisms can enhance process control by allowing for real-time monitoring and adjustments. A control valve that aligns with these essential criteria will not only improve fluid management but also contribute to overall system efficiency and reliability in industrial applications.

Top 10 Control Valves and Their Key Features

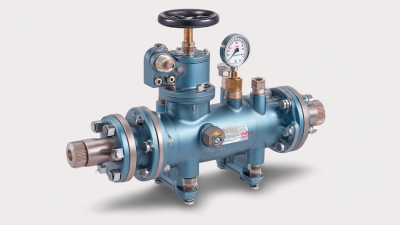

Control valves play a crucial role in regulating fluid flow within industrial applications, ensuring the efficiency and safety of processes. The top ten control valves vary significantly in design and functionality, each tailored for specific operational needs. One popular type is the globe valve, known for its excellent throttling capabilities. It provides precise flow control, making it ideal for applications requiring fine adjustments. Another key feature of globe valves includes their compact structure, which aids in installation in tight spaces while maintaining robustness.

Another notable type is the ball valve, recognized for its quick operation and minimal pressure drop. Its spherical disc allows for smooth flow when fully opened, reducing the risk of turbulence that could impact system performance. Furthermore, the integrity of ball valves makes them suitable for high-pressure scenarios. In contrast, the diaphragm valve offers distinct advantages for handling corrosive and viscous fluids. With its soft sealing design, it minimizes contamination risks and can maintain optimal performance in demanding environments.

Lastly, butterfly valves are favored for their lightweight construction and quick open/close functionality. Their design allows for a wide range of flow control, making them a versatile choice in numerous applications, from water treatment to chemical processing. Each of these valves showcases unique features that enhance operational efficiency, emphasizing the importance of selecting the right control valve for specific industrial requirements.

Advantages of Using Advanced Control Valves in Industries

The use of advanced control valves in industrial applications significantly enhances fluid management, providing industries with improved operational efficiency and reliability. These sophisticated valves are designed to optimize flow control, ensuring that various processes run smoothly and consistently. By allowing precise adjustments to the flow rate, pressure, and temperature, advanced control valves facilitate the fine-tuning of industrial operations, which can lead to substantial energy savings and reduced operational costs.

Furthermore, the benefits of employing advanced control valves extend beyond efficiency. They incorporate innovative technologies that increase durability and reliability, minimizing the risk of failures or downtime. Many control valves are equipped with smart features, such as real-time monitoring and automated feedback systems, which enable industries to respond quickly to any fluctuations in system conditions. This proactive approach not only enhances safety but also contributes to the longevity of equipment and infrastructure, ultimately driving greater productivity and profitability in industrial settings.

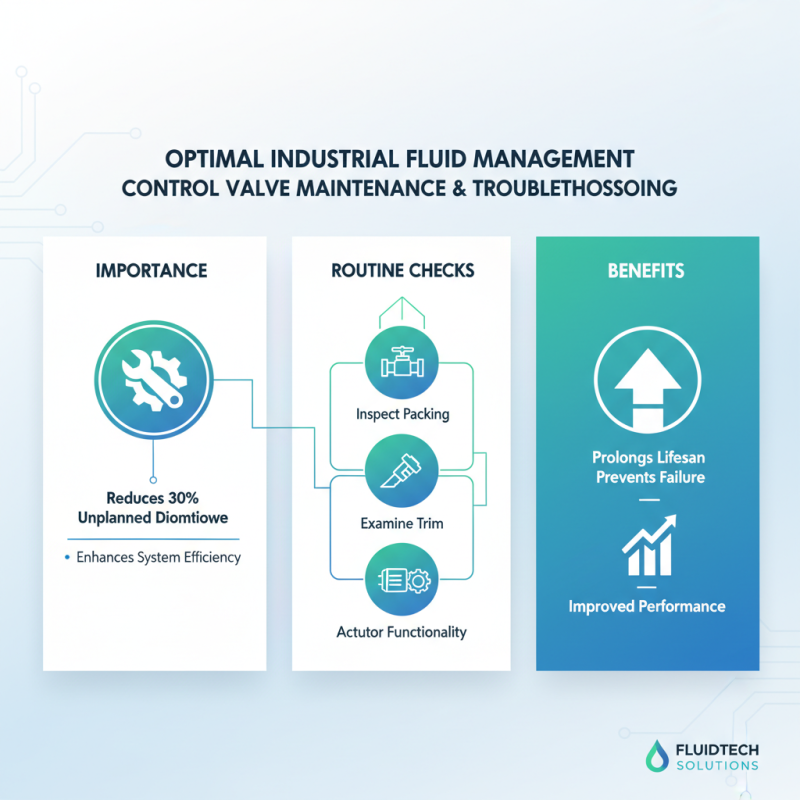

Maintenance and Troubleshooting Tips for Control Valves

Maintenance and troubleshooting of control valves are critical for ensuring optimal performance in industrial fluid management systems. Regular maintenance can significantly reduce the likelihood of valve failure, which industry data suggest accounts for roughly 30% of unplanned downtime in manufacturing processes. Implementing routine checks such as inspecting packing, trim, and actuator functionality can prolong the lifespan of control valves and enhance overall system efficiency.

In troubleshooting scenarios, it is essential to utilize data-driven approaches. For instance, analyzing flow characteristics and pressure differentials can often identify issues such as cavitation or valve dead zones. According to a report by the Fluid Control Institute, nearly 25% of control valve issues stem from improper sizing or installation, which highlights the importance of evaluating specifications against operational requirements. Additionally, integrating predictive maintenance technology can help identify wear patterns before they lead to failure, thus ensuring reliability and minimizing maintenance costs. Recognizing these factors and maintaining vigilant oversight can lead to more effective fluid management across various industrial applications.

Related Posts

-

7 Compelling Reasons to Choose Industrial Control Valves for Your Global Sourcing Needs

-

Top 10 Applications of the Best Pneumatic Solenoid Valves in Industrial Automation

-

Emerging Trends in Pressure Valve Technology for 2025 Shaping Industry Standards

-

Essential Factors to Consider When Selecting the Best Pneumatic Control Valve

-

Exploring the Future of Pneumatic Control Valves: Innovations and Best Practices for 2024

-

Ultimate Guide to Sourcing the Best Pressure Control Valves for Your Needs